What is 2205 Duplex Stainless Steel Casting?

Duplex stainless steel is called “duplex” because they have a two-phase microstructure consisting of grains of ferritic and austenitic stainless steel. Duplex 2205 stainless steel is a high-quality nitrogen-enhanced duplex stainless steel alloy. Duplex Stainless Steel 2205 is also called Duplex 2205. It contains 22% chromium, 6% nickel, 3% molybdenum. 2205 Duplex Stainless Steel Casting takes 2205 duplex stainless steel as raw cast material.

In the stainless steel casting process, it provides incredibly good strength against fatigue and excellent corrosion protection against pitting, erosion, cracking. These features make it suitable for the stainless steel investment casting process.

Duplex 2205 stainless steel casting provides nearly double the corrosion resistance and mechanical strength in other austenitic stainless steels. 2205 duplex stainless steel castings are widely used in industries such as petrochemical,oil and gas,ocean, sporting.

Duplex Stainless Steel 2205 Equialvals

The most widely used duplex stainless steel grade is 2205 Grade. Also Known as: UNS: UNS S31803 – UNS S32205; ASTM A182 (F51), A182 (F60), A240, A276, A479, A480, A789, A790, A815, A928, A988; SAE J405 SAF: SAF 2205® 22Cr; ASME SA-182 (F51), SA-182 (F60), SA-240, SA-798, SA-790, SA-815; Corrosion Resistance:

Chemical Compostions (JIS G 4305- 005) (wt%)

| Content | C | Si | Mn | P | S | Cr | Ni | Mo | N |

| Standard | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.03 | 21.0~24.0 | 4.5~6.5 | 2.5~3.5 | 0.08~0.2 |

| General | 0.025 | 0.6 | 1.5 | 0.026 | 0.001 | 22.5 | 5.8 | 3.0 | 0.16 |

Performance supplement: main components: 22Cr-5.3Ni-3.2Mo-0.16N.

National standards: NAS 329J3L, UNS S32205/S31803, DIN/EN 1.4462, ASTM A240, ASME SA-240.

Mechanical properties:

- Tensile strength: σb≥640Mpa.

- Elongation: δ≥25%.

- Hardness (HB) MAX :217

- Typical working conditions: 20% dilute sulfuric acid, below 60 °C.

- Annual corrosion rate <0.1mm.

- Matching wire: ER2209.

Advantages of 2205 Duplex Stainless Steel Casting

Strength

Duplex stainless steel castings are about twice as strong as regular austenitic or ferritic stainless steel castings.

Toughness and ductility Duplex stainless steel castings have significantly better toughness and ductility than ferritic stainless steel castings.But, they do not reach the excellent values of austenitic stainless steel castings.

Stress corrosion cracking resistance

Duplex stainless steels show very good stress corrosion cracking resistance, a property they have “inherited” from the ferritic side. Stress corrosion cracking can be a problem under certain circumstances (chlorides, humidity, elevated temperature) for standard austenitic castings.

Corrosion resistance

As with all stainless steels, corrosion resistance depends mostly on the composition of the stainless steel castings. For chloride pitting and crevice corrosion resistance, their chromium, molybdenum and nitrogen content are most important. Duplex stainless steel casting grades have a range of corrosion resistance.

Cost

Duplex stainless steel castings have lower nickel and molybdenum contents than their austenitic counterparts of similar corrosion resistance. Due to the lower alloying content, duplex stainless steels can be lower in cost, especially in times of high alloy surcharges.

Applications of 2205 Duplex Stainless Steel Casting

- Chemical process vessels

- Food processing equipment

- Oil field piping and heat exchangers

- Bleach washers, pulp mill digesters

- Flue gas desulfurization equipment

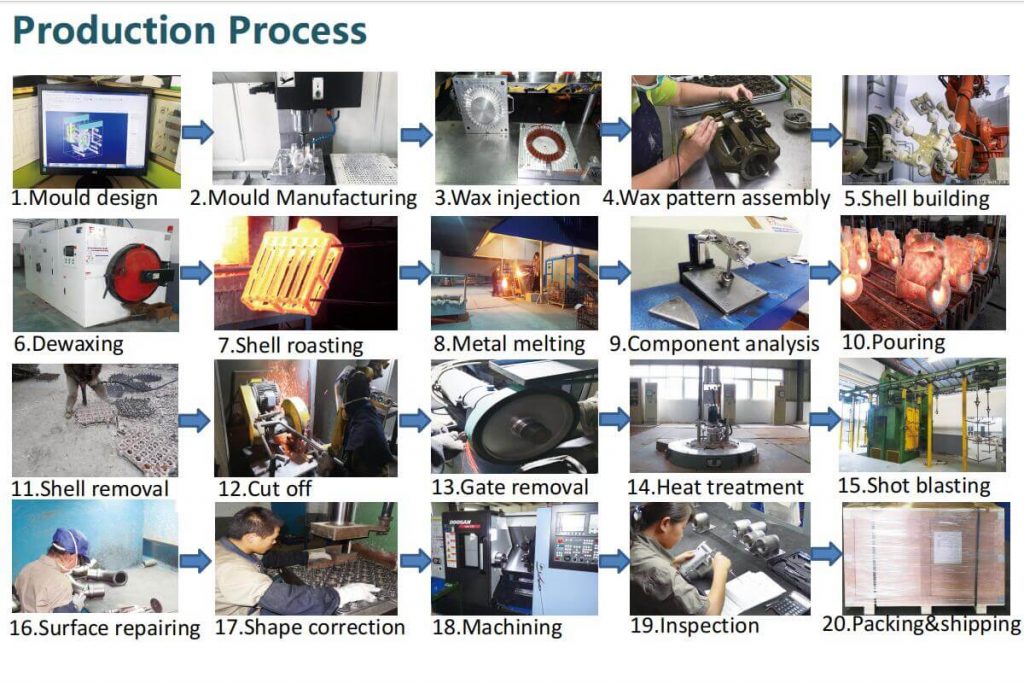

2205 Duplex Stainless Steel Casting Process

2205 duplex stainless steel casting process is actually a lost wax casting process. Its process is the same as the investment casting process.

If you need a large 2205 duplex stainless steel casting part. Sand Casting will be the best choice.

Sand Casting Step

- CREATE A MOLD

- PREPARE AND CLAMP THE MOLD

- POUR MOLTEN METAL INTO MOLD

- ALLOW METAL TO COOL

- REMOVE HARDENED CASTING FROM MOLD

- TRIM EXCESS METAL FROM FINAL CASTING

- POLISH & FINISH FINAL PRODUCT

China JC Casting Foundry for Duplex Stainless Steel Castings

JC Casting is a customized duplex stainless steel casting facory and manufacturer. Our production capability of duplex stainless steel casting weight can range from 10g to 200kg. The maximum overall size is 1,000mm * 650mm * 400mm. The minimum wall thickness is 0.5mm.

In China, only a few stainless steel foundries can manufacture 2205 duplex stainless steel castings. But in JC Casting Foundry, you can get a good solution for your duplex stainless steel casting project.

We keep positive communication with our customers to ensure that we fully understand our customers’ requirements. And to produce it in the most cost-effective manner. If you need a duplex stainless steel casting company for your project, kindly get in touch with us now.