JC Casting is a Silica sol investment Casting manufacturer. Stainless steel castings and alloy steel castings are widely gotten by this process. If you have an inquiry about High dimensional accuracy,Good surface finish casting part,Silica Sol process will be the best choice!

What is Silica Sol Casting

Silica sol Casting, also known as Silica sol investment casting,silica sol precision casting or Silica solution casting,is a common lost wax investment casting process. It uses silica sol (silica solution) as the binder material to build the casting mold. It can withstand a temperature up to 1600-2000 degrees. The metal investment castings produced by silica sol casting have great surfaces and high accuracy. The dimensional tolerance grade can reach CT4 – CT6. RA can reach Ra3.2-6.3.

What is Silica Sol Casting

Silica sol Casting, also known as Silica sol investment casting,silica sol precision casting or Silica solution casting,is a common lost wax investment casting process. It uses silica sol (silica solution) as the binder material to build the casting mold. It can withstand a temperature up to 1600-2000 degrees. The metal investment castings produced by silica sol casting have great surfaces and high accuracy. The dimensional tolerance grade can reach CT4 – CT6. RA can reach Ra3.2-6.3.

What is Silica Sol? https://en.wikipedia.org/wiki/Colloidal_silica

Silica Sol Casting Advantages

- High dimensional accuracy:The general dimensional tolerance grade can reach up to CT4 – CT6, ensuring that the castings meet precise specifications.

- Good surface finish:The process results in smooth surface finishes with no parting line, reducing or even eliminating the need for extensive machining and finishing.

- Versatility: Suitable for casting a wide range of metals, including stainless steel and alloy steel, enhancing its applicability in various industries.

- Capability for complex geometries: It can produce intricate castings with thin walls, ideal for applications requiring complex shapes that may be challenging to achieve with other casting methods.

Silica Sol Casting Process

- Wax injection: A metal die is made first, and then wax is injected into the die to create a wax pattern that is identical to the desired casting.

- Assembly: Multiple wax patterns may be assembled together to form a tree-like structure for efficient casting.

- Shell preparation: The wax pattern is dipped into a slurry of silica sol and refractory powder multiple times. After each dipping, the coating is dried and hardened to build up a strong and durable shell around the wax pattern.

- De-wax: The wax is removed from the shell by heating it, usually in a steam or hot water bath. The wax melts and flows out, leaving a hollow cavity in the shell that is the exact shape of the desired casting.

- Pouring: Molten metal is poured into the prepared shell cavity.

- Cut-off and finishing: After the metal has cooled and solidified, the shell is removed, and the casting is cut off from the tree-like structure. Additional finishing processes may be carried out to achieve the final desired shape and surface quality.

Post Treatments in JC Casting can be provided: CNC Machining, Heating Treatment,Polishing,Coating etc.

JC Casting Silica Sol Casting Capability

- Liner tolerance: ±0.1mm,CT6 according to ISO 8062 (wall thicknesses CT7)

- Surface finish: Ra6.3.

- Weight Range: 0.01kg to 100 kgs.

- Maximum dimensions: 1000 x 620 x 380 mm

- Cast min. hole: Φ2mm

- Cast min. round corner: R0.1mm

- Cast min thickness: 0.6mm

- Angle tolerances: ± 1°

Silica Sol Investment Casting Applications

Aerospace industry:Used for manufacturing components such as turbine blades, engine parts, and structural components that require high precision and complex geometries.

Automotive industry: Applied in the production of engine parts, transmission components, and other critical parts where high accuracy and quality are essential.

Medical industry:Used for manufacturing medical implants, surgical instruments, and other medical devices that require precise dimensions and high-quality surfaces.

Silica Sol Investment Casting Products

Silica Sol Casting Foundry

JC silica sol precision castings are widely used in food machiner, marine casting, medical casting industry. Such as meat grinder parts, valve castings, pump castings, marine hardware.

In JC foundry, all the stainless steel castings are produced by the silica sol casting process. Stainless steel 304,304L,316,316LM17-4,2205 are the main material grades for sIlica sol castings. The casting unit weight can reach 100kg. Our finished Silica Sol Casting are mainly exported to Japan, USA, Itlay, Japan. France and UK…

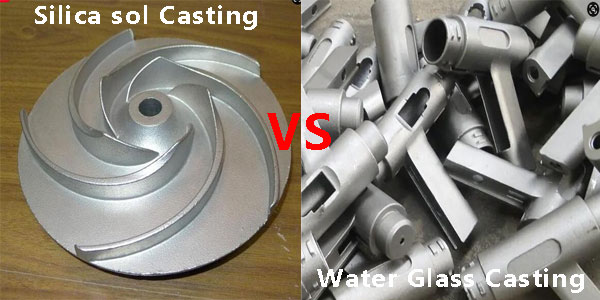

PS: When mentioned Silica Sol Casting, we have to make a compare with Water Glass Casting

Silica Sol Casting vs Water Glass Casting

Both silica sol investment casting and water glass casting belong to lost wax casting or Investment casting. So process of silica sol casting is almost the same as water glass casting. But silica sol investment casting process uses silica sol zircon sand as the molding material. It can bear 2000 degrees temperatures. Water glass casting use waster glass.

Below are the main differences between silica sol casting and water glass casting.

| Process | Cost | Size tolerances | Machining | Material |

| Silica sol casting | high | CT5-6 | No or less machining | Stainless steel |

| Water glass casting | Low | CT7-8 | More machining | Carbon steel & alloy steel |

If with one sentence to conclude the difference: It is the medium temperature wax casting vs low-temperature wax casting.

For more details, you can view the article: Silica Sol Casting VS Water Glass Casting

No matter silica sol casting and water glass casting, if you have requirements, contact us freely. WhatsApp :+86 181 054 67890 . Email: info@jccasting.com