What is a brass valve body

The brass valve body is a core valve component made of brass (copper-zinc alloy). It is used to control the flow direction, pressure and flow of liquid or gas in a pipeline. It is a key component in industries, construction, water supply systems and other fields. JC Casting is a professional brass valve body manufacturer and supplier. Provide high-quality brass valve bodies.

Classification of brass valve bodies

Based on structure and function. Brass valve bodies can be divided into the following categories:

Globe valve body: used to completely open or cut off the fluid. It adopts a straight-through structure. It has the characteristics of small flow resistance and good sealing performance. It is particularly suitable for working conditions that need complete fluid cut-off.

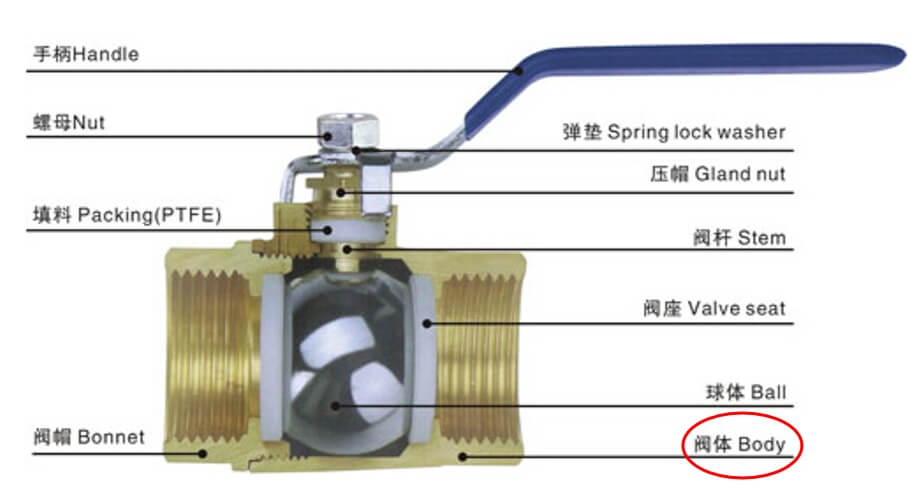

Ball valve body: controls the flow rate by rotating the ball. Good sealing performance. Easy to operate. Quick opening and closing. Its full-bore design makes the fluid resistance very small. It is particularly suitable for occasions that need quick cutting and flow adjustment.

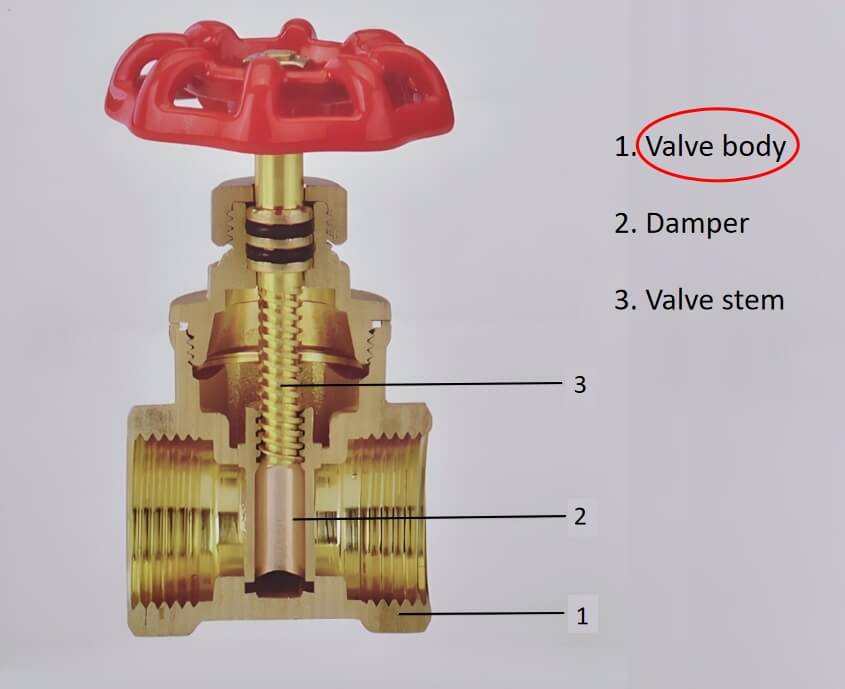

Gate valve body: adopts parallel gate structure. It has the characteristics of extremely small flow resistance. It is suitable for high-pressure and large-diameter pipeline applications. It is especially suitable for working conditions that need full opening and closing. It is also easy to maintain.

Angle valve body: adopts 90-degree angle design. It has the dual functions of changing flow direction and throttling. The compact structure saves installation space. It is especially suitable for use at pipe bends. Commonly used in household and industrial pipelines.

Uses of brass valve bodies

Brass valve bodies are widely used in the following fields:

Industrial pipelines: fluid control in the petroleum, chemical, power and other industries.

Building water supply and drainage: valve components for tap water and heating and ventilation systems (HVAC).

Fire protection systems: high-pressure resistant design ensures reliability in emergency situations.

Ships and automobiles: resistant to seawater corrosion and high temperature environments.

Why choose brass as valve body material?

Brass valve body has irreplaceable advantages over other materials (such as cast iron, plastic):

- Strong corrosion resistance: rust resistance. Especially suitable for water, steam and weak acid and alkaline media.

- High mechanical strength: excellent pressure bearing capacity. Long service life.

- Easy processing: suitable for precision casting. High surface finish.

- Environmentally friendly and safe: meets drinking water standards (such as RoHS). Lead-free brass is more suitable for food-grade applications.

JC’s casting process and features

JC uses precision casting (Investmetn casting) and sand casting technology. Ensure the optimal balance between valve body performance and cost:

Precision casting process:

Suitable for valve bodies with high precision and complex structures. The dimensional tolerance can be controlled within ± 0.1mm.

No sand holes or pores on the surface. Reduce post-processing costs.

Sand casting process:

Suitable for mass production. High cost-effectiveness. At the same time, heat treatment is used to improve strength.

JC’s unique technology:

X-ray flaw detection: 100% full inspection of internal defects. Eliminate hidden dangers.

Nickel plating/chrome plating process: Optional surface treatment. Further extend corrosion resistance.

Brass Valve Body Manufacturer JC Casting – Factory and Capacity Display

As a brass valve body manufacturer and company with 20 years of experience. JC’s core strengths include:

Own production base: 2 modern factories. Equipped with CNC machine tools and automated production lines. Monthly production capacity reaches 1 million pieces.

Global service network: products are exported to 35 countries. Cooperating customers include well-known companies in the fields of petroleum, construction, etc.

Full process quality control: from raw materials (high-quality H59/H62 brass ingots) to finished products. Strictly follow ISO 9001 standards.

One-stop service: support customized design. Fast proofing (3 days for sample production). Mass production and logistics distribution.

We are factory and supplier of brass valve bodies. If you have any needs, welcome send us drawings for consultation.