A380 Aluminum Die Casting

A380 die casting refers to the manufacturing process of metal casting parts by die casting. A380 aluminum alloy is one of the most commonly used die casting material today. It has an excellent combination of castability and properties.

JC Casting is a leading A380 die casting foundry in China. We specialize in manufacturing the A380 aluminum alloy into high quality precision casting parts. Our expertise in this field ensures that every product meets the highest industry standards. To understand A380 die casting, we have to first understand A380 aluminum alloy.

A380 Alloy Composition

Silicon, the main alloying element, enhances the alloy’s fluidity, allowing it to fill complex molds during die casting. Copper, on the other hand, improves tensile strength and hardness, although it slightly reduces corrosion resistance.

| Element | Copper (Cu) | Iron (Fe) | Magnesium (Mg) | Manganese (Mn) | Nickel (Ni) | Silicon (Si) | Tin (Sn) | Zinc (Zn) | Aluminum (Al) |

| Percentage | 3 – 4% | ≤1.3% | ≤0.1% | ≤0.5% | ≤0.5% | 7.5 – 9.5% | ≤0.35% | ≤3% | Balance |

A380 die cast aluminum properties

Mechanical Properties of A380

hese properties enable A380 – cast parts to withstand significant loads and stresses, making them suitable for demanding applications

| Property | Value |

| Hardness, Brinell | 80 |

| Tensile Strength, Ultimate (MPa) | 324 |

| Tensile Strength, Yield (MPa) | 159 |

| Elongation % in 2in. (51mm) | 3.5 |

Physical Properties of A380 Aluminum

Here are some key physical properties of the alloy.

| Thermal Conductivity (W/m °K) | 96 |

| Electrical Conductivity %IACS | 23 |

Advantages of A380 Aluminum Die Casting

Excellent castability and machinability

A380 has high flowability. Complex shapes with tight tolerances can be produced. Reduced secondary operations: A380 die cast parts are easily machined, drilled and tapped. Simplifies post-casting operations.

Ideal strength-to-weight ratio and mechanical strength

The alloy also offers significant strength and hardness. Capable of withstanding high mechanical loads. Ensures its durability in die castings for the automotive, aerospace and other industries.

Corrosion resistance

A380 forms a protective oxide film on its surface. This makes it suitable for harsh environments or wet conditions. Surface treatment processes such as anodizing and powder coating. Corrosion resistance can be enhanced.

Strengthened by heat treatment and cost-effective

A380 can be heat-treated. This improves mechanical properties such as hardness and strength. The alloy is easy to obtain. The price is relatively low. It is compatible with high-pressure die casting processes. It can be produced in large quantities quickly.

Versatile surface treatment and wide application adaptability

It can be used in a variety of surface treatment. This improves appearance and enhances corrosion resistance.

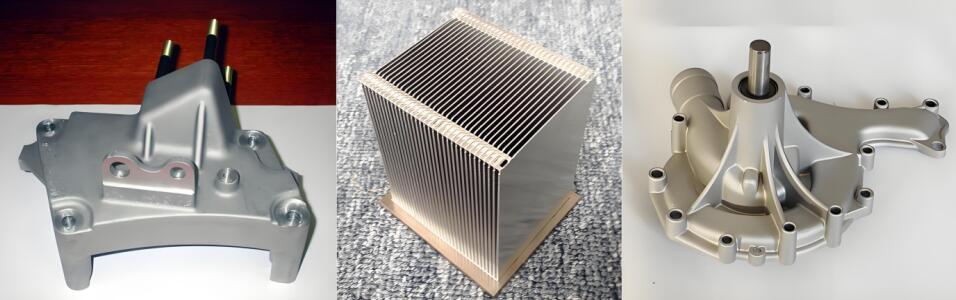

Applications of A380 Aluminum Die Castings

1. Automotive industry

A380 is widely used in the automotive industry for engine parts, gearbox housings and brackets. It has high strength, good durability and light weight. It helps to improve fuel efficiency and automobile performance.

2. Electronics

With thermal conductivity and electromagnetic shielding properties, A380 is used in electronic housings for LED lighting and telecommunication equipment.

3. Power Tools and Machinery

For the production of power tools, machinery housings and components, A380’s strength, durability and ease of processing make it the best choice.

4. Household appliances

A380 die castings can be used for household appliances. such as refrigerators, air conditioners and kitchen appliances. It is lightweight, corrosion-resistant and aesthetically pleasing.

A380 Aluminum Die Casting Foundry Manufacture

JC Casting is a trusted A380 aluminum die casting manufacturer. We take high pressure die casting process,committe to delivering top die casting products. The max weight A380 products we manufacture is 10.5kg. Our own the first level facilities and experienced team ensure that we can meet the diverse needs of our customers. To providing high – quality A380 die – cast components with short lead times.

RFQ

Work on with us

To find a reliable A380 aluminum die casting company,choose JC Casting!