There are various Surface Treatment Processes for metal casings. These treatment methods can improve the corrosion resistance, hardness, aesthetic appearance and other properties of the aluminum alloy surface. Today, let’s introduce the 10 types of metal surface treatment methods.

What is the Surface Treatment Processes?

Surface treatment refers to a series of processes and techniques used to change the surface properties of materials. It aims to improve the appearance, performance, and durability of the material surface.

The purpose of the Surface Treatment

- Enhancing Appearance: Decoration

- Improving Performance:Corrosion Resistance,Wear Resistance,Friction Reduction,Enhanced Adhesion

10 Types of Metal Surface Treatment Processes

Anodizing

Anodizing is a process that enhances the hardness and corrosion resistance by forming an oxide layer on the aluminum alloy casting surface. This oxide film usually also provides the option of dyeing to change the appearance of the aluminum alloy.

Electrophoretic Coating

Electrophoretic coating is a method to form a uniform and strongly adherent coating on the surface of the aluminum alloy. This coating generally has excellent corrosion resistance and abrasion resistance.

Powder Coating

Powder coating is to spray powder onto the surface of the aluminum alloy and then cure it at a high temperature. This coating provides a good appearance and corrosion resistance.

Powder Coating parts

Chemical Chromating

Chemical chromating is a method to improve the corrosion resistance of the aluminum alloy surface. It can also change the color of the surface and provide a protective coating.

Sandblasting

Sandblasting is to use high-speed spraying of sand or other granular materials to change the texture and appearance of the aluminum alloy surface. It also helps to remove dirt and oxides on the surface.

Mechanical Polishing

Mechanical polishing is to improve the smoothness and gloss of the aluminum alloy surface through mechanical methods. Such as grinding or polishing.

Polished casting parts

Coating Oxidation

This is a method of forming an oxide layer on the surface of the aluminum alloy. Then apply a coating to provide extra protection and decorative effects.

Brushing

Brushing is to form elongated horizontal textures on the surface of the aluminum alloy through mechanical ways to change its appearance. It also helps to cover up some surface defects.

Sandblasting and Anodizing

This is a method that combines sandblasting and anodizing. The surface texture is formed by sandblasting. Then the hardness and corrosion resistance are enhanced by anodizing.

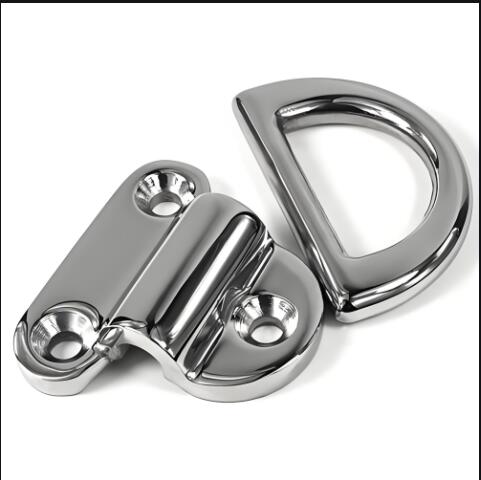

Electroplating

Electroplating is to coat a layer of metal ( such as chromium or nickel ) on the surface of the aluminum alloy. It can improve its hardness and change its appearance.

These surface treatment methods can be used alone or in combination. The specific choice depends on the required performance and appearance requirements. Each surface treatment method has its unique advantages and applicable scenarios.