Leading Automotive Parts Manufactured by Casting Techniques

Automotive casting parts include engine blocks, cylinder heads, transmission cases, subframes, chassis parts, wheels, brake components, and body structural parts. These parts support vehicle performance and safety. Engine blocks and cylinder heads drive a 7.5% annual growth rate, showing their demand in improving fuel efficiency. Aluminum die casting produces lighter parts, reducing vehicle weight by up to 40%. High-pressure die casting tools often last for 75,000 to 200,000 cycles, helping manufacturers create strong, reliable components quickly.

Key Takeaways

- Casting creates strong, lightweight automotive parts that improve vehicle safety and fuel efficiency.

- Aluminum die casting is popular for making engine blocks, cylinder heads, and transmission cases due to its strength and light weight.

- Different casting methods like sand, investment, and die casting offer unique benefits for various automotive parts.

- Advanced casting techniques reduce production costs, allow complex designs, and support faster manufacturing.

- Leading suppliers like JC Casting drive innovation with high-quality materials and automated production to meet growing market demands.

Casting in Automotive Manufacturing

Casting Methods

Automotive manufacturers use several casting methods to create strong and precise parts. Casting means pouring liquid metal into a mold to form a solid shape. Each method offers unique benefits for different automotive casting parts.

- Sand Casting: This method uses sand molds. It costs less and works with many metals. However, it gives a rough surface and lower accuracy.

- Investment Casting: This process creates detailed and smooth parts. It works well for complex shapes but costs more.

- Die Casting: High-pressure die casting injects molten metal into steel molds. It produces parts quickly and with high accuracy. This method is common for making engine blocks and transmission cases.

- Permanent Mold Casting: This uses reusable molds and gravity to fill them. It works for many metals and gives good strength.

- Centrifugal Casting: The mold spins to spread the metal. This makes dense, round parts like bushings.

- Shell Molding: This uses resin-coated sand for precise, complex parts with a good finish.

Quality control is very important in casting. Factories use special machines and tools to check for defects and make sure each part meets safety standards.

The table below compares some popular casting methods:

| Casting Method | Advantages | Limitations |

|---|---|---|

| Sand Casting | Low cost, flexible material choice | Rough finish, less accurate |

| Investment Casting | High accuracy, smooth finish | Higher cost, smaller parts |

| Die Casting | Fast, precise, good for thin walls | High tooling cost, non-ferrous metals only |

Materials Used

Aluminum and its alloys play a key role in automotive casting parts. Aluminum die casting makes lightweight parts that help cars use less fuel. These parts resist rust and last longer. Aluminum also recycles easily, which helps the environment.

Researchers compare different aluminum alloys to find the best mix of strength, weight, and cost. They use special tests to measure how well each alloy flows, shrinks, and resists cracking. High-pressure die casting works well with aluminum alloys. It creates thin, complex shapes with tight tolerances. This process supports the trend toward lighter, more efficient vehicles.

Other materials, such as magnesium and high-strength steel, also appear in automotive casting. However, aluminum remains the top choice for many structural and engine parts because of its balance of performance and cost.

Key Automotive Casting Parts

Engine Blocks

Engine blocks form the core of every vehicle’s engine. They house cylinders and support moving parts like pistons and crankshafts. Manufacturers often use high-pressure die casting with aluminum alloys to create engine blocks. This method produces strong, lightweight parts that help vehicles use less fuel. Aluminum casting also allows for complex shapes and internal passages, which improve cooling and performance. Prototyping and pre-production casting let engineers test and refine engine block designs before mass production. This process reduces risks and ensures that each engine block meets strict quality standards.

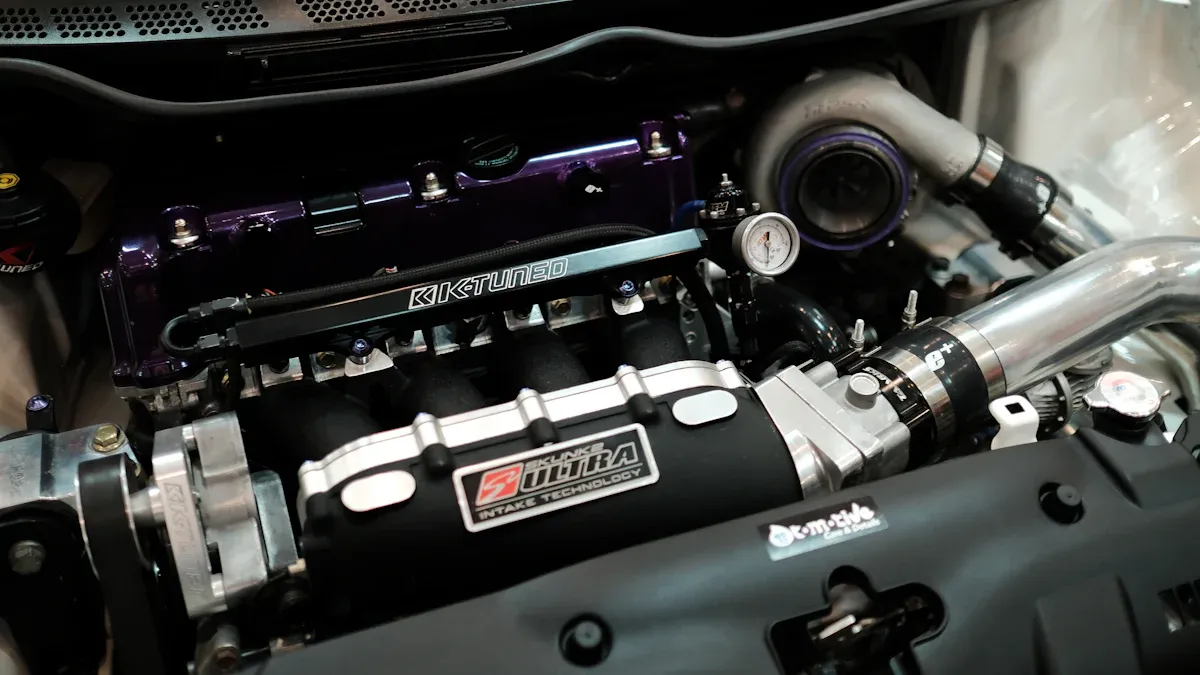

Cylinder Heads

Cylinder heads sit on top of engine blocks and seal the combustion chamber. They contain passages for air, fuel, and exhaust gases. Precision is critical for cylinder heads, so manufacturers use die casting with aluminum alloys like ADC12. This process achieves tight tolerances, often within ±0.05 mm, and produces parts with excellent machinability and corrosion resistance. Automated quality control, including AI-based inspection, helps minimize defects. Advanced tooling can produce over 100,000 cylinder heads before needing replacement. Careful control of melt temperature, mold temperature, and injection pressure ensures consistent quality and durability.

Note: Die casting methods, such as cold chamber die casting, allow rapid production of detailed cylinder heads with minimal post-processing.

Transmission Cases

Transmission cases protect gears and other moving parts in the vehicle’s transmission system. Alloy casting, especially with aluminum and magnesium, is common for these parts. This method offers high accuracy and strength, making transmission cases durable under extreme conditions. Die casting enables complex shapes and reduces the need for extra machining. The process also ensures a high strength-to-weight ratio, which improves vehicle performance and fuel efficiency. Manufacturers can tailor the mechanical properties of transmission cases to meet specific needs, such as heat resistance and ductility.

- Die casting produces transmission cases with excellent tensile strength and fatigue resistance.

- Complex geometries can be made in one step, reducing assembly time and improving structural integrity.

- Optimized die design and high-quality alloys help maintain product reliability.

Subframes and Chassis

Subframes and chassis parts provide the main structure for vehicles. They support the engine, suspension, and body. Large-format aluminum high-pressure die casting, sometimes called mega-casting, simplifies production by reducing the number of parts. This approach lowers complexity and cost while improving strength and integration. Companies like GF Casting Solutions use casting to create lightweight, high-quality subframes that absorb vibrations and support heavy components. The Audi e-Tron and Ford F-150 use cast aluminum subframes for durability and corrosion resistance. Combining castings with extrusions allows for rapid prototyping and reduces welding, making production faster and more efficient.

Wheels

Wheels must be strong, safe, and lightweight. Casting methods, such as low-pressure die casting, are widely used to produce aluminum wheels. These processes create wheels with high tensile and yield strength, which improves safety and performance. Certification by organizations like the Aluminium Stewardship Initiative confirms that cast wheels meet strict quality and environmental standards. Optimized heat treatment of Al-Si-Mg alloys further enhances mechanical properties. The table below shows the improved strength of cast wheels compared to standard alloys:

| Alloy Composition | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|

| AlSi9Mg0.2 | 260.88 – 279.39 | 185.01 – 202.48 |

| AlSi9Mg0.3 | 276.0 – 287.27 | 199.11 – 210.0 |

Brake Components

Brake components, such as calipers and rotors, require optimal strength and wear resistance. Casting methods, especially liquid state fabrication like stir casting, are effective for producing metal matrix composites (MMCs) used in brakes. Aluminum-based MMCs with reinforcements like silicon carbide (SiC) and titanium diboride (TiB2) offer high tensile strength, hardness, and fracture toughness. The stir-casting process allows precise control over the material’s properties, resulting in brake components that perform well under stress and resist wear over time.

- Casting improves fatigue behavior and wear resistance in brake parts.

- Proper selection of matrix and reinforcement materials enhances mechanical performance.

Body Structural Parts

Body structural parts, such as crossmembers and shock towers, provide strength and rigidity to the vehicle’s frame. High-pressure die casting and giga-casting produce large aluminum alloy parts with excellent mechanical properties. These parts must withstand fatigue, collision loads, and harsh conditions. Hybrid manufacturing, which combines sheet metal with cast reinforcements, can achieve up to 18% weight savings compared to casting alone. This approach supports lighter, more efficient vehicles. Process optimization and careful control of casting parameters help ensure that body structural parts meet demanding safety and durability standards.

Automotive casting parts like these benefit from advanced casting techniques, which reduce part count, lower costs, and improve performance. Industry examples show that integrated casting can reduce the number of parts in a vehicle from over 170 to just a few, cutting costs and increasing productivity.

Benefits of Automotive Casting Parts

Strength and Weight

Automotive casting parts offer a strong balance between durability and lightness. Manufacturers use high-pressure die casting to create parts that support heavy loads while keeping weight low. For example:

- Die-cast brackets can hold over 100 kg and handle strong industrial forces.

- Aluminum alloys like A380 provide high strength, corrosion resistance, and good heat flow.

- Typical brackets weigh between 0.5 kg and 1.2 kg, with wall thicknesses from 2.5 mm to 4.0 mm.

Giga Casting 2.0 technology helps make large, single-piece aluminum parts. Tesla’s Model Y uses this method to replace 171 smaller parts with just two big castings. This change makes the car lighter and stronger by removing welds and seams. Adding nanotechnology to casting also boosts strength by about 30% and improves wear resistance. These advances help automotive casting parts meet strict safety and performance standards.

Design Flexibility

Casting methods give engineers the freedom to design complex shapes. The CMI Novacast Electromagnetic Pump lets foundries make detailed cylinder heads and gearboxes with high precision. Zinc die casting supports thin walls, fine details, and tight tolerances. Aluminum alloys can be shaped into many forms, which helps brands like Audi, Jaguar, and Tesla build lighter, safer cars. These materials can be adjusted for strength, ductility, or corrosion resistance, making automotive casting parts suitable for many uses.

Design flexibility in casting allows for creative solutions and supports new vehicle designs.

Cost Efficiency

Casting stands out for its cost efficiency, especially at high production volumes. The global automotive casting market reached $72.03 billion in 2023 and is expected to grow by 5.8% each year until 2032. Asia-Pacific leads this growth due to lower costs and strong investments. The table below compares casting with other methods:

| Aspect | Casting | CNC Machining | 3D Printing | Sheet Metal Fabrication |

|---|---|---|---|---|

| Best for | Large volumes | Prototypes, low runs | Prototypes, <100 | Simple shapes |

| Per-part cost | Drops with volume | Higher at scale | High at scale | Varies |

| Material efficiency | Over 95% | 30-70% waste | Varies | Varies |

| Design complexity | High | Limited | Limited | Limited |

Casting uses materials well and reduces waste. Although the initial tooling cost is high, the price per part drops as more units are made. This makes automotive casting parts a smart choice for car makers who need many strong, complex parts.

Automotive Casting Parts Suppliers

JC Casting Overview

JC Casting stands out as a leading supplier in the automotive casting industry. The company has developed a high-performance aluminum-silicon alloy that meets the strict needs of new energy vehicles. This alloy offers top yield strength, tensile strength, and thermal conductivity. JC Casting maintains a product qualification rate above 99%. For two years, the company has held over 35% of the domestic market share in the new energy vehicle segment. Their lightweight materials help customers reduce component weight by more than 30%, which increases vehicle range.

JC Casting’s R&D team includes more than 150 experts. They work with universities and industry leaders to drive innovation. The company uses spectrum analysis to test material stability and coordinate measurement for micron-level accuracy. Non-destructive testing, such as X-ray flaw detection, ensures structural integrity. JC Casting has more than 60 fully automatic production lines and over 80 patents. The company’s annual production capacity reaches 50,000 tonnes. Strategic partnerships, like those with BYD, support joint development of lightweight body parts for electric vehicles.

| Metric/Aspect | Details/Value |

|---|---|

| Casting qualification rate | Over 98% |

| Production efficiency | 20% higher than traditional processes |

| Annual production capacity | 50,000 tonnes |

| Number of fully automatic lines | More than 60 |

| Patents obtained | Over 80 |

| Operating income (2024) | Exceeded 690 million yuan |

Industry Leaders

The global market for automotive casting parts features many strong competitors. Companies like Hitachi Metals, Dynacast, Nemak, and GF Casting Solutions lead the industry. These suppliers focus on advanced metallurgy, precision die casting, and sustainability. Many companies expand into electric vehicle segments and form strategic partnerships. Mergers and acquisitions, such as Rheinmetall’s recent purchase of a die-casting firm, show how suppliers seek to boost their capabilities.

Key players include Alcast Technologies, Ahresty Corporation, Calmet Inc, and Magna International. The Asia-Pacific region holds over half of the market share, while the United States leads in metal casting. Market drivers include the demand for lightweight materials and the rise of electric vehicles. Technological advances, such as 3D printing and CAD/CAM integration, help suppliers stay competitive. The market for automotive casting parts reached $177.28 billion in 2024 and is expected to grow quickly.

The competitive landscape remains dynamic, with suppliers investing in innovation and expanding their global reach.

Automotive casting parts remain essential for vehicle strength, safety, and efficiency. Casting methods offer high precision, cost savings, and design flexibility. Recent advancements include improved mold materials, automation, and 3D printing.

- The investment casting market is growing, driven by demand for lightweight, complex parts.

- Sand casting continues to evolve with better materials and sustainability.

Suppliers like JC Casting help the industry meet new challenges and support innovation.

FAQ

What is the main benefit of using casting for automotive parts?

Casting creates strong parts with complex shapes. Manufacturers can make many parts quickly. This process also helps reduce waste. Many car makers choose casting for its cost savings and design flexibility.

Which metals are most common in automotive casting?

Aluminum is the most common metal. It is light and strong. Some parts use magnesium or steel. These metals help cars last longer and use less fuel.

How does casting improve vehicle safety?

Casting allows engineers to design parts that absorb impact and support heavy loads. Strong cast parts help protect passengers during accidents. Quality checks ensure each part meets safety standards.

Can casting methods help make electric vehicles better?

Yes. Casting makes lightweight parts for electric vehicles. Lighter cars use less energy and travel farther. Many electric car makers use advanced casting to improve battery range and strength.

How do manufacturers check the quality of cast parts?

Factories use X-rays, spectrum analysis, and special machines to find defects. They measure each part to make sure it fits. These checks help keep cars safe and reliable.