What is the difference between Cast Aluminum and Cast Iron? Cast Aluminum Vs Cast Iron? Today, let’s discuss this topic!

What is Cast Aluminum?

Cast aluminum is a type of aluminum that is produced by pouring molten aluminum into a mold. The aluminum solidifies and takes on the shape of the mold. Cast aluminum is often used in the production of automotive parts and lawn furniture. Because they require a strong and lightweight material.

What is Cast Iron?

Cast iron is a group of iron-carbon alloys with a carbon content greater than 2%. They are made by melting iron and mixing it with scrap metals and other materials. Such as carbon, silicon, and manganese, then pouring it into a mold to solidify. Cast iron is known for its high compressive strength. Also in excellent machinability and good wear resistance. It is commonly used in construction, manufacturing, and engineering applications. Such as pipes, engine blocks, cookware and more. It is also used in the manufacturing of some tools and machine parts due to its durability and strength.

The Advantages and Disadvantages of Cast Aluminum

Cast aluminum is a strong, lightweight, and durable material. Which is suitable for a wide range of applications. It has several advantages including its strength-to-weight ratio. Which makes it ideal for use in vehicles and other applications where weight is a concern. Below are its advantages:

- Strong-to-weight ratio

- High temperature resistance

- Corrosion resistance

- Good machinability

- Cost-effective:

Cast aluminum, like any other material, has some disadvantages. One of the main disadvantages is its low tensile strength compared to other metals. Which makes it less suitable for applications that needed high strength in tension. Listed below are the summary of its disadvantages:

- Low tensile strength

- Porosity

- Limited design freedom

- Scrap generation

- Finishing process

The Advantages and Disadvantages of Cast Iron

Cast iron is a group of iron-carbon alloys with a high compressive strength, excellent machinability, and good wear resistance. It is commonly used in construction, manufacturing and engineering applications. Below is the summary of its advantages:

- High compressive strength

- Excellent machinability

- Good wear resistance

- Low cost

- Easy to cast

Cast iron, like any other material, has some disadvantages. Cast iron is also brittle and can break or crack under stress. It is heavy and may not be suitable for applications where weight is a concern. Here is the summary of its disadvantages:

- Low tensile strength

- Brittle

- Heavy

- Rusts

- Expensive to repair

Difference Between Cast Aluminum And Cast Iron

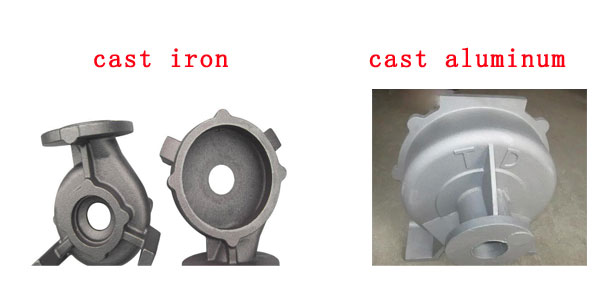

Cast aluminum and cast iron are both metals. They are used for a wide range of applications, but they have some key differences.

| CAST ALUMINUM | CAST IRON | |

| Composition | Made primarily of aluminum | Group of iron-carbon alloys with a carbon content greater than 2% |

| Strength | relatively low compressive strength but a relatively high tensile strength | high compressive strength but relatively low tensile strength |

| Weight | Light 2.7g/cm3 | Much heavier 7.8g/cm3 |

| Machinability | relatively easy to machine, but it is less brittle than cast iron | relatively easy to machine |

| Corrosion resistance | resistant to corrosion | prone to rusting |

| Cost | more expensive than cast iron | relatively inexpensive |

| Temperature Resistance | high-temperature resistance and is less brittle at low temperatures | withstand high temperatures but is brittle at low temperatures |

| Applications | used in the production of automotive parts, lawn furniture. and other items that require a strong and lightweight material | used in construction, manufacturing and engineering applications. such as pipes, engine blocks, cookware and more |

How to choose Cast Aluminum Vs Cast Iron

It is wrong to choose a material regardless of the purpose or application!

For example Motor Shell (housing)

- The motor shell is cast iron. Durable. It can stand beating. High mechanical strength.

The disadvantage is that it is relatively heavy. Easy to rust. The heat dissipation is worse than that of aluminum.

- The motor shell is aluminum. Beautiful, not easy to rust, easy to process, good heat dissipation performance. But the mechanical strength is poor. The cost is also high. The price is also high.

JC CASTING

At JC Casting, we can use the sand casting process or die casting process for custom aluminum castings and iron castings by cast iron and cast aluminum. We offer a wide range of custom metal casting and fabrication services. And our team is committed to meeting your casting needs. Contact us today to learn more about how we can help with your casting projects!