Bronze impellers have excellent corrosion resistance, wear resistance and mechanical properties. They are widely used in water pumps, chemical equipment and other fields. JC Casting is a bronze impeller casting manufacture and supplier. From design to production, we control the whole process and provide customers with high-quality bronze impellers.

Definition and Features of Bronze Impeller Casting

Bronze impellers are rotating parts cast from bronze alloys. They are usually used to transport liquids or gases. Bronze plays an important role in impeller manufacturing:

Corrosion resistance: Tin or aluminum in bronze forms a dense oxide film with copper. It can effectively isolate the corrosion of corrosive media (such as seawater, acid and alkali). Suitable for ships and chemical equipment.

Wear resistance: The hard phase in the bronze alloy increases the surface hardness. It ensures that the impeller is not easy to wear during long-term high-speed operation. Extend the service life.

Good mechanical properties: The copper matrix gives toughness. Alloy elements (tin, aluminum, etc.) enhance strength. Bronze has both impact resistance and load-bearing performance. It can withstand dynamic loads under complex working conditions.

The bronze impellers produced by JC Casting not only have the above-mentioned general advantages, but also further improve the performance and reliability of the product through precision casting and other processes.

Bronze Impeller Casting Application

Bronze impellers are widely used in the following fields:

- – Shipbuilding industry: used for seawater pumps, propulsion systems.

- – Chemical equipment: transporting corrosive media. Such as acid and alkali solutions.

- – Energy industry: used for cooling systems, circulating water pumps.

- – Municipal engineering: key components in water supply and drainage systems.

JC Casting’s impeller products have successfully served many well-known companies around the world. Customers cover Europe, North and South America and Asia.

Bronze Impeller Casting Material considerations: performance first

JC Casting recommends the following bronze alloys:

– Tin bronze (such as C90300): high strength and corrosion resistance. Suitable for high load conditions.

– Aluminum bronze (such as C95400): better corrosion resistance and wear resistance. Suitable for chemical and marine environments.

We work with high-quality material suppliers. Ensure that the raw materials meet international standards. And pass strict factory inspection. Guarantee product quality from the source.

Bronze Impeller Casting Methods: Precision Casting and Sand Casting

JC Casting mainly uses two casting processes: precision investment casting and sand casting. We can flexibly choose the most suitable solution according to customer needs.

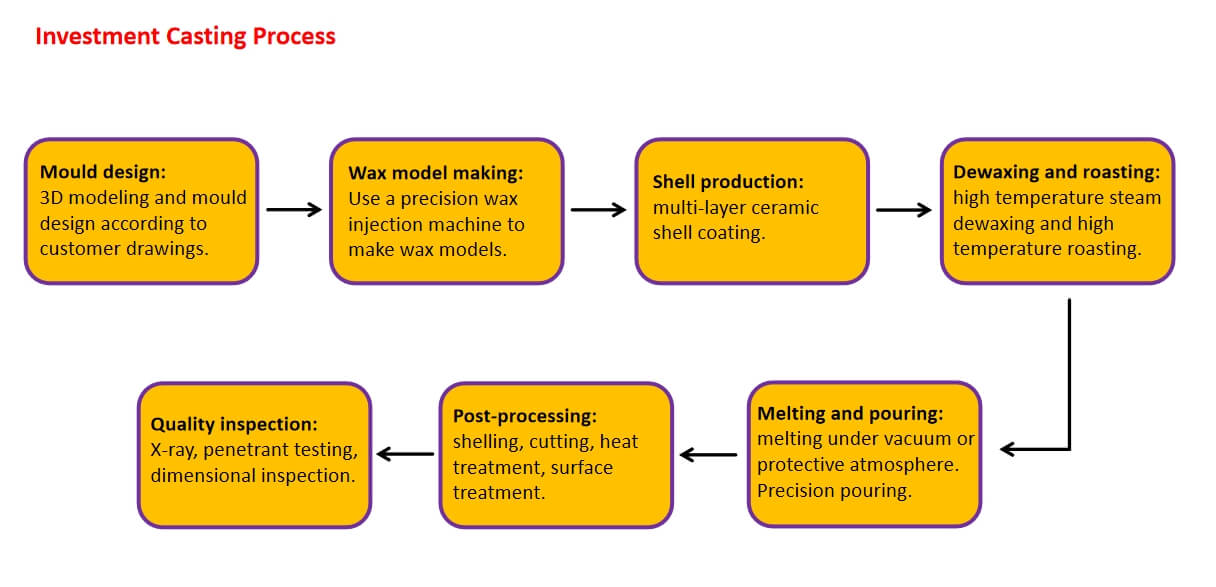

Precision casting (lost wax investment casting)

Process:

1. Make wax molds and assemble them into tree-like structures.

2. Apply multiple layers of refractory materials to form a shell.

3. Dewax and high-temperature roast the shell.

4. Pour bronze molten metal.

5. Remove the shell after cooling. Carry out subsequent processing.

Key points:

– High precision: can produce impellers with complex shapes and precise dimensions. High surface finish. Reduced subsequent processing.

– Suitable for small batch or customized production.

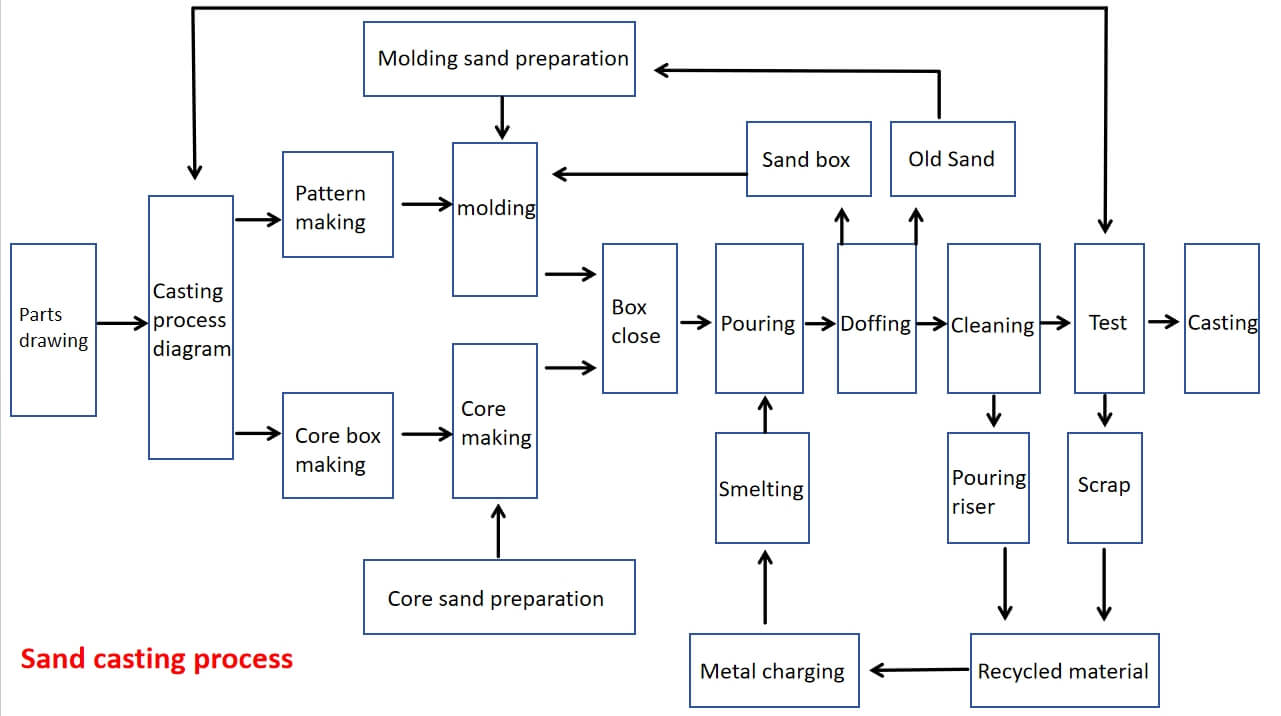

Sand casting

Process:

1. Make a wooden or metal mold.

2. Use the mold sand to shape the part.

3. Pour the molten bronze.

4. Remove the casting after cooling. Clean and process.

Key points:

– Low cost. Suitable for mass production.

– Ensure the internal quality of castings by optimizing sand mold design and process parameters.

Bronze Impeller Casting Foundry –JC Casting

– Independent factory and CNC machine center: From casting to finishing, the whole process is completed independently. Ensure quality control.

– Mature technology: more than 20 years of experience accumulation. Able to accurately control each process. Reduce the defect rate.

– Support customization: Whether it is precision casting or sand casting. The process parameters and design can be adjusted according to customer needs.

– One-stop service: from design, casting to processing and testing, full support.

– Quick response: professional team provides technical support and after-sales guarantee.

Reliable guarantee: a partner trusted by customers

JC Casting has won the recognition of many customers with reliable quality and excellent service. Our cooperative customers include:

– World-renowned pump manufacturers

– Marine equipment suppliers

– Leading companies in the chemical industry

Customer feedback shows that our bronze impellers excel in performance, life and service. If you have bronze impeller requirements, kindly send your drawings and requirements to our team.We will reply it within 12 hours. info@jccasting.com