Aluminum die casting is a high-pressure metal forming process used to produce complex, thin-walled, and dimensionally consistent aluminum components at scale. It is widely applied in industries where precision, repeatability, and production efficiency are critical.

At JC Casting, aluminum die casting is positioned as a mass-production manufacturing solution, not a prototyping process. We support customers from mold development to stable long-term production, ensuring consistent quality across every production batch.

What Is Die Casting?

Die casting is a type of metal casting process. Under high pressure, It forces molten metal into a mold cavity formed by two dies to cast a casting part. The common metal is aluminum or aluminum alloys. The pressure is usually 10–140 megapascals. That’s why it’s sometimes called high-pressure die casting. This process shares similarities with the plastic manufacturing process of injection molding. It is one of the most popular process of metal casting. Due to its high accuracy, good quality, and ability to create detailed components.

Compared with sand casting or investment casting, die casting is especially suitable for:

- High-volume production

- Thin-wall and complex geometries

- Tight dimensional consistency

- Good surface finish directly from the mold

Usually, non-ferrous metal alloys with a low melting point are raw materials. Such as zinc, copper, aluminum, magnesium, lead, tin, tin-based alloys. According to the type of metal being cast, there are Hot Chamber Die Casting Method and Cold Chamber Die Casting Method

Die Casting Types

Hot Chamber Die Casting Method

Hot Chamber Die Casting – Best for low-melting-point metals like zinc. The injection mechanism is submerged in molten metal.

This process is used for low-melting alloys. Such as zinc, lead, tin, magnesium alloys. One feature of hot chamber die casting machines is that the casting chamber is constantly in contact with the liquid alloy. The melt passes through a valve into the casting chamber. At there, it is pressed at high speed into the closed die casting mold by the piston. Hot-chamber die casting is a great option for alloys that do not readily attack and erode metal pots, cylinders, and plungers.

Cold Chamber Die Casting Method

Cold Chamber Die Casting – Used for high-melting-point metals like aluminum. The molten metal is ladled into the chamber for each shot.

This process is better suited for metals with high melting points such as aluminum, copper.In the cold chamber die casting process, metal is liquefied. Then ladled into a cold chamber. At there, a hydraulically operated plunger pushes the metal into the mold. After the alloy has been pressed into the mold in both processes, the component solidifies under strong pressure. Then remove from the mold. t can be further processed if necessary.

Advantages and Disadvantaged of Die Casting

Advantages:

– High production rate

– Tight tolerances (±0.002 in.)

– Smooth surfaces (can eliminate machining)

– Thin-walled parts possible

– Good strength-to-weight ratio

Disadvantages:

– High initial die cost (justified for large production runs)

– Not economical for small batches

– Limited to non-ferrous metals (typically)

Die casting Applications

Die casting is used in industries such as:

– Automotive (engine parts, transmission housings)

– Aerospace (lightweight components)

– Electronics (heat sinks, connectors)

– Consumer goods (appliance parts, power tools)

– Medical devices (precision instruments)

How are Die Castings Made?

To produce tens of thousands of castings at high speed, the steel mold must be made in at least two sections to allow the castings to be removed. These parts are firmly mounted in the machine and are arranged so that one is stationary (fixed die half). The other one is movable (syringe half-mold). To begin the casting cycle, the two mold halves are clamped together by a die-casting machine. Molten metal is injected into the mold cavity and rapidly solidified. The mold half is opened and the casting is ejected. Die-casting molds can be simple or complicated, with moveable slides, cores, or other parts. This is depending on the complexity of the casting.

Until now, the die casting cycle has been the fastest cycle to produce precision nonferrous metal parts. This is in stark contrast to sand casting. It requires new sand molds for each casting. Although the permanent mold process uses iron or steel molds instead of sand. It is much slower and less precise than die castings.

Aluminum Die Casting Process

1. Mold Preparation

Before casting begins, the die is cleaned and sprayed with a release and cooling agent. This step helps control mold temperature, ensures smooth part ejection, and extends mold life.

The mold is then closed and clamped under high locking force to withstand injection pressure.

2. Aluminum Melting

Aluminum alloy ingots are melted in a controlled furnace. Common die casting alloys such as A380 or ADC12 are selected for their fluidity, strength, and casting performance.

The molten aluminum temperature is carefully monitored to ensure stable flow and minimize defects.

3. High-Pressure Injection

Molten aluminum is injected into the die cavity at high speed and high pressure. This rapid filling allows the metal to fully reproduce fine details and thin-wall sections of the mold.

High-pressure injection is a defining characteristic of the aluminum die casting process and distinguishes it from gravity or sand casting.

4. Cooling and Solidification

Once the cavity is filled, the aluminum solidifies quickly inside the steel mold. Cooling channels within the die help control solidification rates, reduce porosity, and improve dimensional stability.

Proper cooling design is essential for consistent quality in mass production.

5. Part Ejection

After solidification, the die opens and ejector pins push the casting out of the mold. The cycle time is short, allowing for high production output.

Excess material such as runners and gates is removed for recycling.

6. Trimming and Finishing

The cast part undergoes trimming to remove flash and gating. Depending on functional requirements, secondary operations may include:

- CNC machining

- Drilling or tapping

- Surface treatments such as powder coating or anodizing

Many aluminum die cast parts require minimal machining due to the process’s dimensional consistency.

Die Casting Material Types

| Material | Tensile Strength (Mpa) | Thermal Conductivity (W/mK) | Features |

|---|---|---|---|

| Aluminum A380 | 325 | 96 | Best combination of mechanical, casting, and the thermal properties.Excellent fluidity, pressure tightness, and resistance to hot cracking.Widely used for engine brackets, hand tools, electronic equipment chassis, gearbox cases, and household furniture. |

| Aluminum A360 | 317 | 113 | Excellent pressure tightness and fluidity.High corrosion resistance.High strength in elevated temperatures. |

| Aluminum 413 | 295 | 121 | Good combination of casting, mechanical, and thermal properties.Excellent fluidity, pressure tightness, and resistance to hot cracking. |

| Aluminum 383 | 310 | 96 | Often used for highly intricate components.Good corrosion resistance, lightweight. Good combination of casting, mechanical, and dimension stability. |

| Aluminum B390 | 317 | 134 | High hardness and good wear resistance.Suitable for internal combustion engine pistons, cylinder bodies for compressors, and brakes. |

| Aluminum A413 | 290 | 121 | Excellent pressure tightness.Good choice for hydraulic cylinders. Suitable for die casting intricate components. |

| ZAMAK 2 | 359 | 105 | Excellent damping capacity and vibration attenuation.Superior to other Zamak alloys with creep performance.High strength and hardness levels after long-term aging |

| ZAMAK 3 | 283 | 113 | Great balance of physical and mechanical properties.Excellent finishing characteristics for plating, painting, and chromate treatments.Good castability and long-term dimensional stability.Good damping capacity and vibration attenuation. |

| ZAMAK 5 | 328 | 109 | Has a higher copper content than Zamak 3, which results in higher strength.Has less ductility than Zamak 3. More readily plated, finished, and machined than Zamak 3. |

| ZA 8 | 374 | 115 | Ideal for decorative application.Excellent finishing and plating characteristics.Good performance of strength, hardness, and creep properties. |

Secondary Operations of Die Casting

- High precision CNC machining, milling, drilling, tapping, e-coating, anodizing

- Painting, sanding, shot blasting, powder coating, chrome plating

Die Casting Mold Development

Die casting molds are a critical investment and determine part quality, consistency, and production efficiency.

At JC Casting:

- Mold design is optimized for aluminum flow and cooling

- Tooling is developed for long-term production stability

- Mold structure is aligned with target annual volume

- Maintenance and lifecycle management are integrated into production planning

This approach ensures predictable output and controlled unit costs over time.

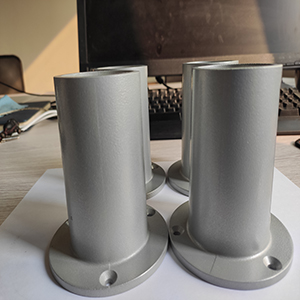

Dimensional Accuracy and Surface Finish

Aluminum die casting delivers:

- Consistent dimensional accuracy suitable for assembly applications

- Smooth surface finish directly from the mold

- Reduced secondary machining compared to other casting processes

Machining is applied only where functional tolerances or assembly interfaces require it.

Quality Control for Mass Production

Our aluminum die casting production follows standardized quality control procedures, including:

- Incoming material inspection

- Process monitoring during casting

- Dimensional and functional inspections

- Consistent batch-to-batch control

This ensures reliability for customers operating continuous or high-volume production programs.

When Die Casting May Not Be Suitable

Aluminum die casting may not be the best option for:

- Very low production volumes

- Extremely thick-walled components

- Parts requiring frequent design changes

In such cases, we recommend alternative processes such as sand casting, gravity casting, or CNC machining.

Aluminum Die Casting Manufacturer – JC Casting

JC Casting is a Aluminum Die Casting foundry-focused aluminum die casting supplier, supporting customers with reliable mass production rather than short-term prototyping.

If you are evaluating aluminum die casting for medium to high-volume production, our engineering team can help assess part feasibility, material selection, and cost structure.

Contact JC Casting to discuss your aluminum die casting requirements.