CNC machining is a precision manufacturing process used to produce metal and plastic components with tight tolerances, excellent accuracy, and high design flexibility. It is especially suitable for prototyping, engineering validation, and low-volume production where speed, precision, and design freedom are critical.

At JC Casting, CNC machining is positioned as a supporting manufacturing process that complements investment casting,sand casting and die casting. It is primarily used for prototypes, functional testing, and low-to-medium volume production before or alongside mass-production processes.

JC Casting CNC Machining Company provides a variety of precision CNC machining services including CNC Milling & CNC Turning. With the lastest manufacturing technology & advanced CNC machines (3-, 4- and 5-axis machine centers), we can customize all shapes of metal parts to your drawing’s specification. No matter it is a small or large production order, we always offer quality products with fast delivery. Contact us today to get a free quote for your project!

What Is CNC Machining?

CNC machining is a subtractive manufacturing process in which computer-controlled machines remove material from solid blocks to create finished parts. Common CNC processes include milling, turning, and multi-axis machining.

Because tool paths are digitally controlled, CNC machining delivers:

- High dimensional accuracy

- Excellent repeatability

- Flexibility for design changes

- Fast turnaround for prototypes and small batches

When CNC Machining Is the Right Choice

CNC machining is most suitable when:

- Parts require tight tolerances or precise geometry

- Production volumes are low to medium

- Designs may change during development

- Fast lead time is more important than tooling cost

It is widely used for functional prototypes, test fixtures, custom components, and early-stage production parts.

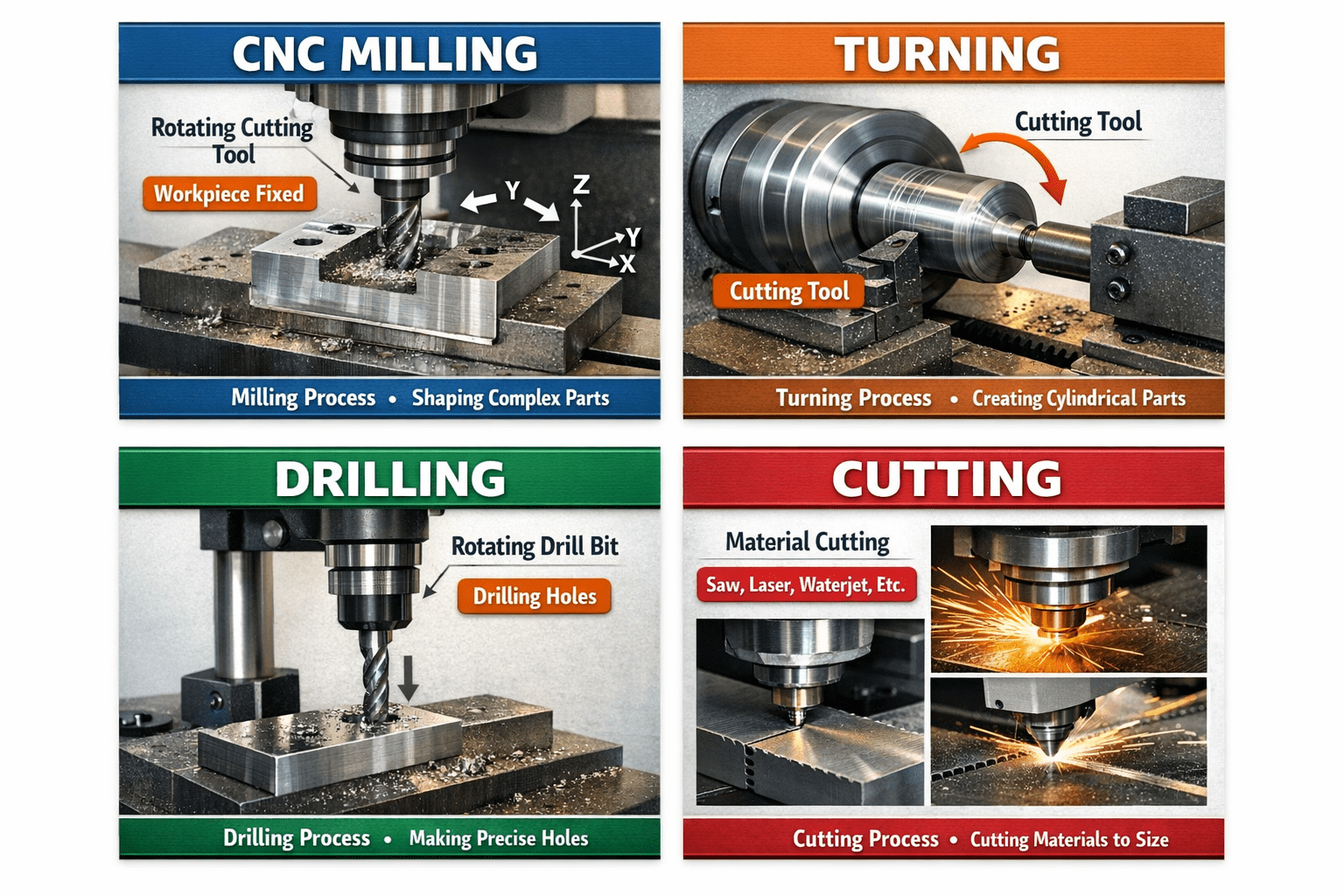

CNC Machining Processes

We support the long-term development of CNC milling services. CNC turning services. CNC milling-turning. CNC drilling services. 3/4/5 axis machining. gear machining services. CNC machining China custom parts and service, small parts machining. Our professional CNC parts machining involves CNC metal parts manufacturing, plastic CNC machining, and some difficult materials. They can be used in a broad range of industries.

1. CNC Milling

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to cut solid plastic and metal blocks into final parts.

2. CNC Turning

CNC turning with live tooling combines both lathe and mill capabilities to machine parts with cylindrical features from metal rod stock.

3. CNC Drilling

Drilling is the cutting process in which the workpiece does notcutter move, aligning the cutter center with the hole center, anc rotate

4. CNC Cutting

CNC cutting is a subtractive manufacturing method that uses a variety of different cutting technologies combined with computer numerical control software to remove excess materials from the block and create specific 2D or 3D shapes.

CNC Drilling

Drilling is the cutting process in which the workpiece does not move, making the cutter move, aligning the cutter center with the hole center, and making the cutter rotate. CNC Drilling is primarily done on CNC machines including CNC milling machines and lathes. CNC drilling service produces round holes, typically for machine screws and bolts. Drilling can process CNC drilling parts with metals, hard plastics, wood and most other rigid materials. There are several types of drilling machines available for CNC, including these drill presses: Upright, Bench and Radial. When in use, the step-by-step process for CNC drilling includes:

- The operator uploads and accesses the computer-aided design (CAD) or computer-aided manufacturing (CAM) file.

- The operator installs the appropriate drill bit and secures the designated material on the table.

- The operator starts the drilling process through the control panel or interface.

- The spindle lowers, drilling the appropriate hole sizes and diameters.

CNC Cutting

Unlike traditional cutting services, CNC cutting is a subtractive manufacturing method that uses a variety of different cutting technologies combined with computer numerical control software to remove excess materials from the block and create specific 2D or 3D shapes. Common CNC cutting machines and tools including laser, water jet, route, plasma, knife, etc. CNC cutting services provide products for aerospace, automotive, chemical, agriculture, military, defense, and more commercial and industrial applications. CNC cutting is widely applied due to its speed, precision and accuracy, as well as little human error. CNC cutting process can be performed alone or with other processes depending on the configuration and purposes.

CNC Cutting Types

CNC Plasma Cutting: a plasma cutting torch is usually used cut through various materials such as stainless steel, mild steel, aluminum, brass, etc., ideal for budget rapid prototyping, large pieces, extended jobs, more. It is the most affordable cutting option.

CNC Laser Cutting: a manufacturing process carried out by CNC laser cutters, lasers can cut a number of materials, even cut through the toughest metals and hardest gemstones with efficiency. It is also an extremely quick process to cut wood and plastic materials to create excellent cut edge quality and an exceptional level of detail. Laser cutting can produce intricate parts to high tolerances with a smooth surface finish.

CNC Waterjet Cutting: this process uses an ultra-high pressure stream of water to carry abrasive grit, which leaves a precise and smooth cut surface on the workpiece. Water jet cutting is the most versatile method to cut almost any material with good surface quality and no heat affected zone, but it is less efficiently compared to the other two cutting techniques

CNC Machining Materials

JC Castring CNC services working with a large selection of metal, plastic and other types of materials

Metals

- Aluminum: 2024, 5083, 6061, 6063, 7050, 7075, etc.

Alloy: brass 360, 101 copper, 110 copper, 932 bronze, zinc, etc.

Titanium: grade 2, grade 5, etc.

Stainless steel: 303, 304, 410, 17-4, 2205 Duplex, 440C, 420, 316, 904L, etc.

Steel: 4140, 4130, A36, 1018

Plastics

- Acetal,CPVC,Delrin (POM),HDPE,LDPE,Nylon,PEEK

PEIPET,PS,PSU,PTFE POM (Delrin), - ABS (Acrylonitrile Butadiene Styrene),

- HDPE, Nylon, PLA, PC (Polycarbonate),

- PEEK (Polyether Ether Ketone),

- PMMA (Polymethyl Methacrylate or Acrylic),

- PP (Polypropylene),

- PTFE (Polytetrafluoroethylene), etc.

Other CNC machining materials: Graphite, VeroClear

Dimensional Accuracy and Surface Finish

CNC machining offers excellent dimensional control and surface quality compared to many forming processes. It is commonly used when parts require:

- Precise mating surfaces

- Tight geometric tolerances

- Consistent dimensions across small batches

Surface finishing options can be applied to meet functional or aesthetic requirements.

Automotive CNC Machining

The automotive industry requires components that are both lightweight and durable, with high precision to meet strict performance standards. CNC machining is often used to produce parts such as:

- Engine components (e.g., cylinder heads, crankshafts)

- Transmission parts

- Steering mechanisms

- Brake components

- Custom tooling and fixtures

By utilizing CNC machining, manufacturers can produce complex automotive parts with the precision required for high-performance vehicles, while ensuring efficient production processes and minimal waste.

Aerospace CNC Machining

Aerospace applications demand the highest levels of precision, durability, and safety. CNC machining plays a critical role in producing parts that meet these stringent requirements, including:

- Aircraft structural components (e.g., wings, fuselage)

- Turbine blades and engine components

- Fasteners and seals

- Flight control systems

With the ability to machine a wide range of aerospace materials, including aluminum alloys, titanium, and high-strength steels, CNC machining ensures the creation of lightweight, strong, and highly accurate components.

Medical CNC Machining

In the medical industry, precision is paramount. CNC machining is used to manufacture parts for medical devices, equipment, and instruments where accuracy can be a matter of life and death. Key applications include:

- Surgical instruments (e.g., scalpels, forceps)

- Implants (e.g., knee joints, hip replacements)

- Diagnostic equipment (e.g., MRI parts, X-ray components)

- Dental devices (e.g., braces, dental implants)

With its ability to create parts with high repeatability and consistency, CNC machining is a trusted solution for medical manufacturers who require parts that meet stringent regulatory standards and exact specifications.

Electronics CNC Machining

The electronics industry relies on CNC machining for the production of parts that are used in consumer electronics, telecommunications, and high-tech equipment. Some common applications include:

- Housings for smartphones, laptops, and tablets

- Enclosures for circuit boards and sensors

- Connectors, terminals, and other electronic components

- Heat sinks for power electronics

CNC machining ensures that these components are made with precise dimensions and tight tolerances, allowing for efficient assembly and reliable performance.

Industrial Equipment CNC Machining

In industrial manufacturing, CNC machining is used to produce parts that support heavy-duty machinery and equipment. Key applications include:

- Custom brackets and mounts

- Gears, shafts, and pulleys

- Hydraulic components (e.g., valves, pumps)

- Bearings and bushings

CNC machining is ideal for producing parts that need to handle high-stress conditions, providing the durability and precision required to maintain smooth operations in industrial settings.

Military and Defense CNC Machining

The military and defense sectors require components that perform under extreme conditions and maintain high levels of reliability. CNC machining is used for producing:

- Weapon parts and accessories

- Armor and protective gear

- Military-grade connectors and fasteners

- Components for unmanned aerial vehicles (UAVs)

With stringent quality control and precision standards, CNC machining ensures that military and defense parts meet rigorous safety, functionality, and durability requirements.

Consumer Products CNC Machining

CNC machining is also widely used to produce parts for consumer products that require intricate designs, consistent quality, and short lead times. Applications include:

- Kitchen tools and gadgets

- Sporting goods and equipment

- Furniture components

- Consumer electronics accessories

Whether it’s a limited-edition product or a custom item, CNC machining offers the flexibility and accuracy needed to produce high-quality consumer goods.

JC Casting Machining Services Benefits

- Rich design and manufacturing experience

- Efficient CNC machining factory for mass production rapid prototyping service

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Fast free quotation within 24 hours after inquiry

CNC Machining Manufacturer – JC Casting

JC Casting is a manufacturing-focused supplier offering CNC machining as part of a complete metal manufacturing solution. We support customers with prototyping, low-volume production, and process transition to casting or die casting when appropriate.

If you are evaluating CNC machining for your project, our engineering team can help assess design feasibility, material selection, and production strategy.

Contact JC Casting to discuss your CNC machining requirements.