About JC CASTING – A Precision Casting Manufacturer You Can Trust

JC CASTING is a professional precision casting manufacturer providing custom metal casting and machining solutions for demanding industries worldwide.

With strong engineering support, strict quality control, and reliable delivery, we help customers turn complex designs into dependable, production-ready cast parts.

From prototype development to mass production, we focus on precision, consistency, and long-term partnership.

Who We Are

JC Casting

—— A Professional Customized Casting Manufacturer for you

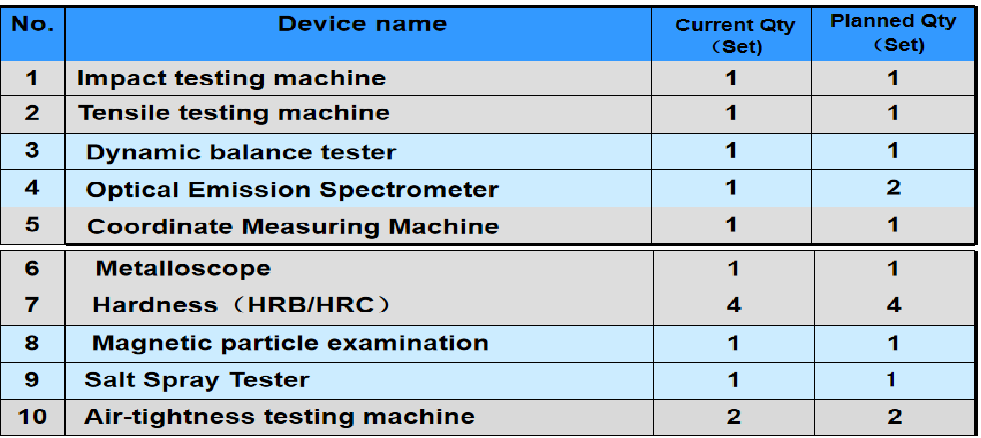

JC Casting is a specialized castings manufacturer including tooling, investment casting, precision, machining, surface treatment and assembly. Our company possesses a full set of precision equipment including Computer Numerical Control lathe and surface processing equipment (polishing、grinding etc.) of casting, heat-treatment equipment, anti-corrosion saline fog testing monitor, pressure examining equipment, special dynamic balance tester, CMM and other machine capability testing equipment. Our company has a specialized investment casting factory with annual output of 500 tons. Our company has abundant experience of casting surface processing, precision machining, we established rigorous quality assurance system and can provide the whole process service from exploitation of precision casting to assembly and finished products.

Our investment casting company has 2 units: one is a foundry, Another one is CNC Machining Factory. There are a total of 210 workers in our factory. Via many years’ hard work, we now have become one of the largest investment casting manufacturers and suppliers.

Our company can cast a variety of materials: Alloy Steel, Carbon Steel, Stainless Steel, Aluminum, etc. With great capabilities of design, molding, casting, machining, and heat treatment.

JC CASTING specializes in precision casting and metal manufacturing for OEM customers across automotive, aerospace, industrial machinery, energy, food machinery, pump & valve, and other critical industries.

We work closely with customers to understand application requirements, performance expectations, and cost targets, delivering casting solutions that balance quality, efficiency, and manufacturability.

Our Technical Strength

Advanced Casting Processes

We offer a comprehensive range of casting and machining processes to meet different structural, material, and performance requirements, including:

- Silica sol investment casting

- Water glass casting

- Sand casting

- Die casting

- CNC machining and secondary operations

This flexibility allows us to support a wide variety of part sizes, complexities, and production volumes.

Engineering & Material Expertise

Our experienced engineering team supports customers throughout the entire project lifecycle — from design review and material selection to process optimization and production validation.

By focusing on manufacturability and performance from the early stages, we help reduce risks, control costs, and ensure stable long-term production.

Quality & Reliability You Can Rely On

Strict Quality Control System

Quality is built into every step of our manufacturing process. From incoming material inspection to in-process control and final inspection, each part is produced under a strict quality management system to ensure dimensional accuracy, material integrity, and performance consistency.

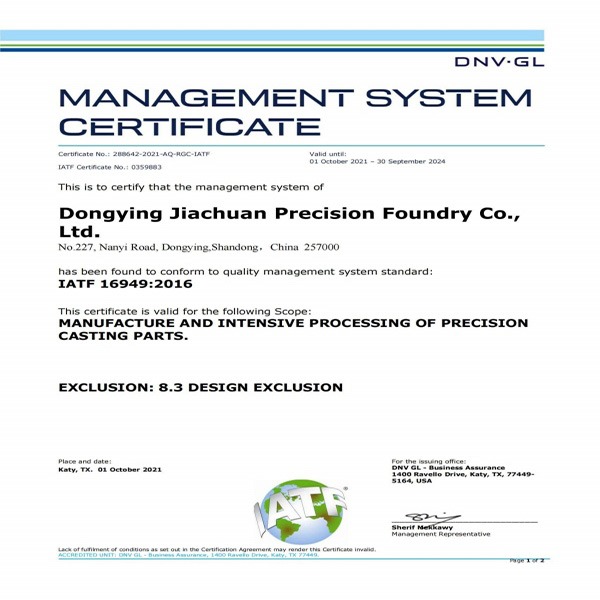

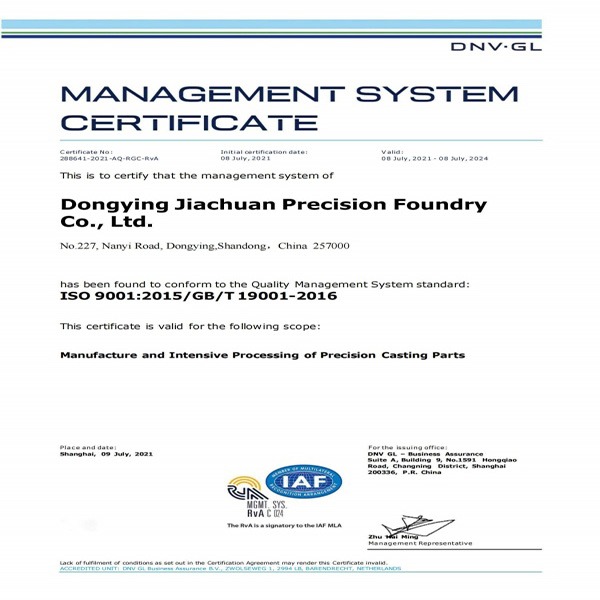

Certifications & Standards

Our manufacturing operations comply with internationally recognized quality standards, including ISO-certified systems. Full inspection records and traceability are available to meet customer and industry requirements.

Manufacturing Facility & Production Capacity

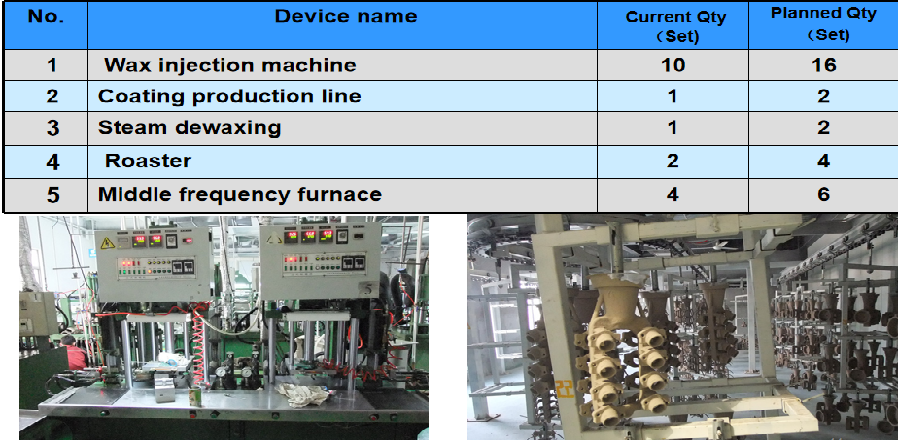

Our modern foundry and machining facilities are equipped to handle both small-batch prototypes and high-volume production.

With stable process control and capacity planning, we support customers with consistent quality, reliable lead times, and scalable production capabilities as projects grow.

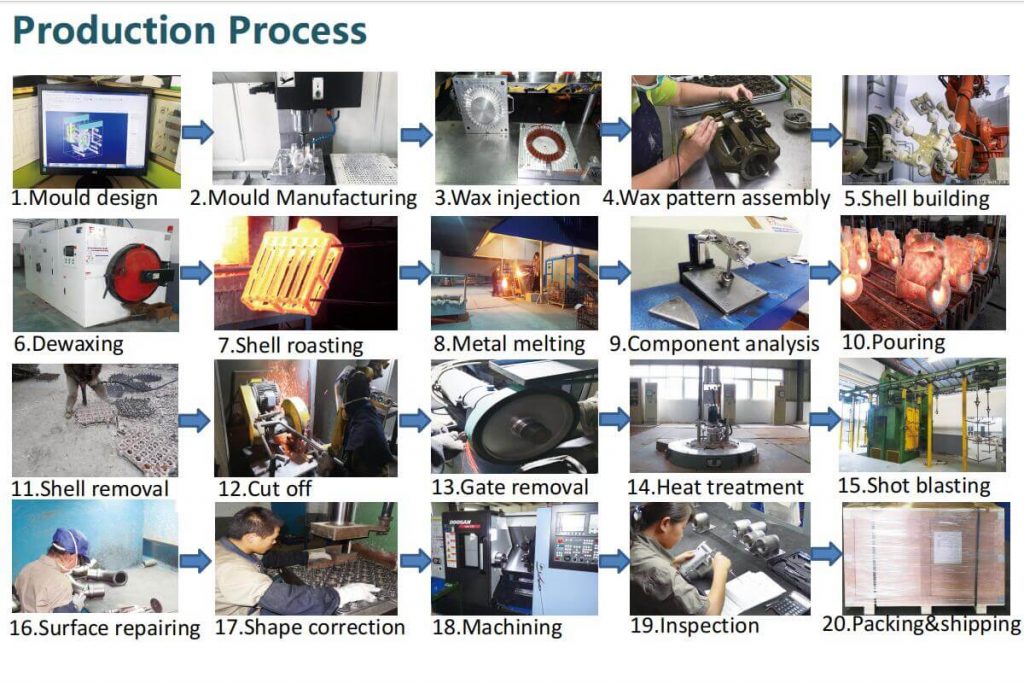

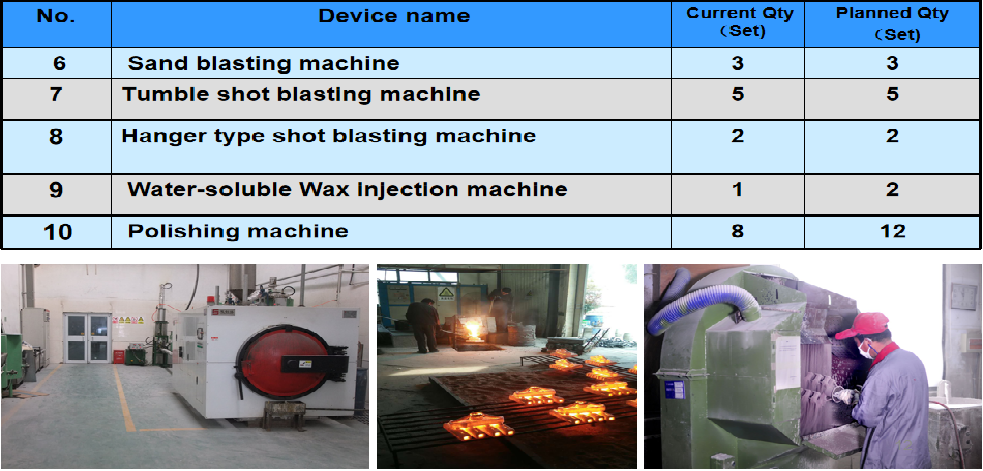

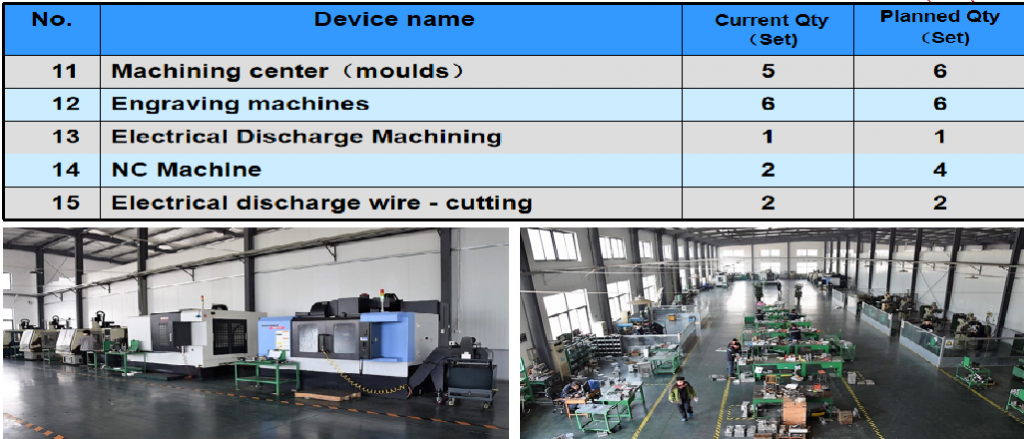

Production Line

Lab and Testing Equipment

Capability

Casting Methods

Silica Sol Casting: Medium temperature lost-wax casting process with general tolerance CT5-CT6. Most Widely used for stainless steel products. Also could be used for precision carbon steel parts. This investment casting method allows casting products to range from 2g to 150 kgs.

Water Glass Casting: Low-temperature lost-wax casting process with general tolerance CT7-CT8. More suitable to produce carbon steel and alloy steel products. The water glass casting capability is to cast products from 0.05kg to 200 kgs.

Sand Casting: Another investment casting technical different from lost wax casting. This kind of casting process can achieve casting tolerance CT8-CT9. The weight of products ranges from 0.5kgs to 25000kgs. The usually used materials are ductile iron, gray iron, high chrome iron.

Die Casting: A high-pressure casting process with a general tolerance of CT4 – CT7. It is used mainly for non-ferrous metals. Such as aluminum, zinc, and magnesium alloys. Aluminum die casting is popular in automotive, electronics, and aerospace. zinc die casting is great for detailed thin-walled consumer and hardware items. Magnesium die casting mostly is in weight-sensitive applications. Die cast products typically range from 1g to 50 kgs. The process is highly efficient for mass production.

Post Treatment

We have a factory of CNC machining. All post-treatment jobs can be finished here. Until now, many domestic investment casting factories send their investment casting products to us.

Industries We Serve

We provide precision casting solutions for industries where performance, durability, and reliability are critical:

- Automotive

- Aerospace

- Industrial Machinery

- Energy & Power

- Food Machinery

- Pump & Valve

- Construction & Mining

Each industry presents unique challenges, and our casting solutions are engineered to meet specific application requirements.

Why Customers Choose JC CASTING

Engineering-Oriented Partnership

We do more than manufacture parts — we work as an extension of our customers’ engineering teams to solve real manufacturing challenges.

Stable Quality & Reliable Delivery

Customers trust JCCASTING for consistent quality, clear communication, and dependable delivery schedules across long-term projects.

Long-Term Cooperation

Many of our customers partner with us for years, relying on our stability, technical capability, and commitment to continuous improvement.

Serving Customers Worldwide

JC CASTING supports customers across North America, Europe, and other global markets, delivering precision casting solutions that meet international technical and quality requirements.

Our experience in global supply chains enables smooth communication, compliance, and project execution.

Let’s Discuss Your Project

Whether you need precision castings for a new design or a reliable foundry partner for ongoing production, our team is ready to support your project.

Contact our engineering team today to discuss your requirements and receive a professional solution.

If You Are Looking for a Reliable Precision Casting Supplier?

Now just tell us what you need. The Exclusive Plan will be delivered immediately.

No matter from Mold, Product Design, Technology Choosing, Cost Control, we have rich experience and professional engineer!

Email: info@jccasting.com

24 Hours WhatsApp: +86 181 054 67890