What is Casting?

Casting is a process in which a material, such as metal, plastic, or glass is heated and then shaped into a desired form by pouring the heated material into a mold. The mold can be made of stone, sand, plaster, wax, clay or some other type of material. Casting is used to make many different things from cookware and jewelry to machine parts. Many metals are commonly used for casting including aluminum, brass, bronze and steel. Each metal has its own properties that make it suitable for different applications.

Advantages of Casting

Casting is a versatile and cost-effective method of manufacturing that offers many advantages over traditional methods of fabrication. It offers greater control over part geometry, improved surface finish and dimensional accuracy, along with design flexibility.

Here’s a summary list of its advantages:

- Cost-effective

- Complex shapes and geometries

- Variety of materials

- High tolerance

- Strength and durability

What is Machining?

Machining is a process of removing material from a workpiece using a cutting tool to achieve the desired shape, size and surface finish. It is a manufacturing method that is used to create a wide range of parts and components for various industries, including aerospace, automotive, medical, and construction. Common types of machining include turning, milling, drilling, grinding, and broaching.

The process is performed using various types of machines, such as lathes, milling machines, and drill presses. The choice of machine and cutting tool used will depend on the material, size, and complexity of the part being machined. Machining is a precise method that allows for tight tolerances and a high level of accuracy in the finished product.

Advantages of Machining

Machining is a precise and versatile manufacturing method that offers several advantages. One of the main advantages is its precision and accuracy, which allows for tight tolerances and a high level of dimensional accuracy in the final product.

Below is the list of its advantages:

- Precision

- Versatility

- Speed

- Customization

- Surface finish

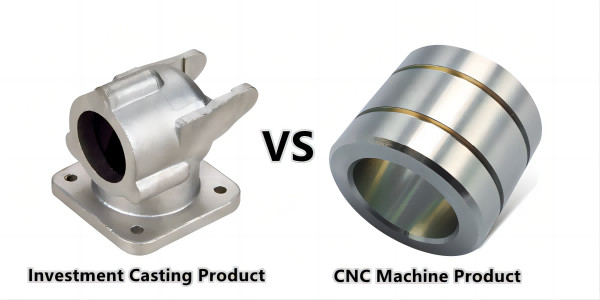

What is the difference between Casting and Machining(Casting Vs Machining)

Casting and machining are two different manufacturing methods that are used to create parts and components. The primary distinctions between them are as follows:

- Manufacturing process

Casting involves pouring molten material into a mold, while machining involves removing material from a solid block or piece using cutting tools.

- Complex shapes

Casting is particularly well-suited for creating complex shapes and geometries that may be difficult or impossible to achieve with other methods, while machining is used to create parts with high precision and accuracy.

- Tolerance

Castings have a higher tolerance than machined parts, meaning that less finishing work is needed after the casting process.

- Surface finish

Machining can produce a smoother surface finish than casting.

- Material

A wide range of materials can be used in casting such as metals, plastics, and ceramics, while machining is mostly used for metals.

- Volume

Casting is typically less expensive than machining, making it ideal for high-volume production, while machining can be more cost-effective for small-batch and prototype manufacturing.

- Customization

Machining is more flexible than casting and allows for more customization of the final product.

- Automation

Many machining processes can be automated, but most casting processes require manual labor.

- Speed

Machining is generally faster than casting.

- Versatility

Machining is more versatile in terms of shapes, sizes and complexities of parts that can be created while casting is limited by the mold design.

JC Casting is a top custom investment casting manufacturer with our own machining workshop. We are a dependable supplier for all your casting needs. We can provide all types of investment casting components in steel, iron, aluminum, and many other materials. Please contact us if you are considering the design of a new part to be cast. Our sales and engineering staff can help you decide which process is appropriate for you.