What is Die Casting?

Die casting is a manufacturing process that involves injecting molten metal into a mold or die to produce parts and components in large quantities. It is one of the most efficient and cost-effective processes for producing complex, precision shapes with tight tolerances. Die casting can be used to create parts in a variety of metals, including aluminum, brass, zinc, magnesium, and copper alloys.

What is Sand Casting?

Sand casting, also known as a sand molded casting, is a metal casting process characterized by using sand as the mold material. The “sand casting” can also refer to an object produced via the sand-casting process. Sand castings are produced in specialized factories called foundries. More than 60% of all metal castings are produced via sand casting process.

Advantages and Disadvantages of Die Casting

The die casting process offers many advantages to manufacturers over other casting methods.

- Die casting is an efficient, cost-effective method of producing a variety of metal parts with an excellent surface finish.

- It also allows for tight tolerances and very precise details to be achieved.

- Die cast parts can also be easily customized by changing dies, which is not possible in some other casting processes.

However, like all manufacturing processes, there are some disadvantages associated with die casting.

- The tooling costs associated with creating the dies can be quite expensive compared to other processes due to the intricate detail required.

- While shorter lead times can usually be achieved with die casting compared to other manufacturing processes, refining the die can add extra time onto production cycles.

- The process of die casting is also highly specialized and requires expert technicians to operate the machinery and create the dies accurately.

- Due to the high temperatures used in the process, some materials are not compatible with die casting and may require alternative processes instead.

Advantages and Disadvantages of Sand Casting?

Listed below are some but not all, pros and cons of sand casting:

Advantages:

- Low cost tooling and production costs due to the fact that sand is an abundant natural resource.

- Sand casting can produce very complex shapes and parts with minimal draft, which makes it ideal for producing intricate designs.

- The process is relatively fast and efficient compared to other metal casting processes.

- The strength of castings produced by this method is comparable to those made with other methods.

- Sand casting offers excellent dimensional accuracy, repeatability, surface finish, and tight tolerances.

Disadvantages:

- Poor surface finish due to the presence of sand grains in the final product. This may require additional finishing or machining operations for certain applications.

- It can be difficult to attain uniform wall thickness when casting very thin sections.

- The process is somewhat time consuming, as the sand must be packed and rammed into the molds in order for them to properly form the desired shape.

- Sand casting requires more labor than other casting processes, making it relatively expensive compared to other methods.

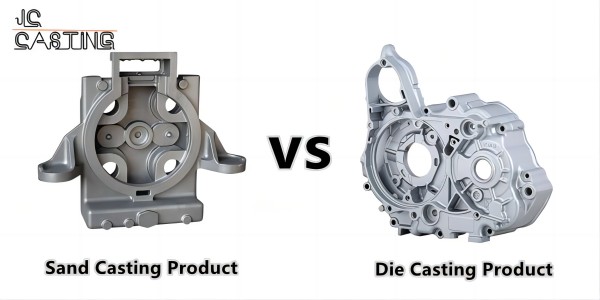

What is the sand casting and die casting difference? (Die Casting VS Sand Casting)

The following table summarizes the key differences between sand and die casting.

| TRAIT | DIE CASTING | SAND CASTING |

| Mold Material | H13 Steel(or equivalent) | Casting Sand |

| Mold Preparation Time | Can be lengthy | Very fast |

| Upfront Costs | High for main equipment, moderate for producing new ones | Relatively Low |

| Production Volumes | Medium to very high | Low to high |

| Product Surface Finish | Excellent or smooth | Depending on sand |

| Possible Product Complexity | Very Complex | Somewhat Complex |

| Dimensional Accuracy | Very Good to Excellent | Poor to Good |

| Cast Sizes | Small to Medium | Medium to Very Large |

| Typical Filling Method | High-Pressure Injection | Gravity Pour |

How to choose to Die Casting VS Sand Casting processing?

1–If you consider the cost element, sand casting is economic.

2–If you focus on quality, die casting is a better choice. Its surface finish and tolerance is better than sand casting.

3–If your mass order quantity is more, die casting is better. Its delivery time is shorter.

JC Casting: THE SOLUTION TO YOUR CASTING NEEDS

Are you looking for a reputable casting manufacturer? we recommend working with us JC Casting. With over 20 years of experience in the industry, JC Casting is a leading provider of high-quality casting solutions. We are confident that they’ll be able to meet your specific needs and requirements. Contact us today to learn more!