Commonly used titanium alloys heat treatment methods are annealing, solid solution and aging treatment.

Titanium alloys are favored by people for their excellent room temperature, high-temperature mechanical properties, outstanding corrosion resistance and high strength. With the development of science and technology, titanium and titanium alloy materials are used in more and more fields. Such as medical, automotive, aerospace, and sports. As a light metal, titanium is increasingly recognized and determined for its excellent properties. Replace other metals at a faster rate. integrated into our production and application areas. even our bodies.

The excellent properties of titanium alloys are shown in

- Low density (4.51g/cm3, 57% of steel)

- High strength (tensile strength 680-1180Mpa)

- High hardness (30-40HRC)

- Wide operating temperature range (high heat 600℃, low temperature -253℃)

- Good corrosion resistance, non-magnetic, low thermal conductivity, low anti-damping performance.

Titanium alloys are divided into α titanium alloys, β titanium alloys and α+β titanium alloys according to their annealed state. These three materials are used in many parts of current new models.

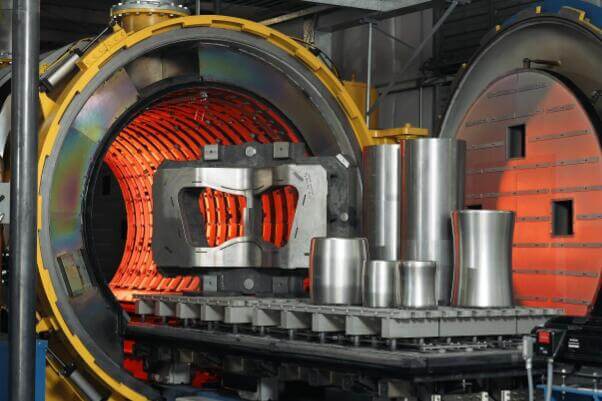

Titanium alloys heat treatment types

Titanium alloys heat treatment significantly increases the strength of the alloys. Get comprehensive properties of high strength and good plasticity. Commonly used heat treatment methods for titanium alloys are annealing, solid solution, and aging treatment.

- Annealing is suitable for all kinds of titanium alloys. Mainly to obtain the best mechanical properties, eliminate stress, improve plasticity and stabilize the organization.

- Solid Solution and aging treatment are the main means of strengthening titanium alloys.

Annealing

Stress relief annealing

The annealing temperature is 100-250°C lower than the recrystallization temperature.

The purpose is to eliminate or reduce internal stress during processing. Prevent and reduce deformation.

Fully annealed

Also known as recrystallization annealing

The annealing temperature is close to the recrystallization temperature and the beta transformation point. The annealing process mainly occurs through recrystallization. The temperature is above the recrystallization temperature of the alloy.

Purpose: to reduce hardness, improve plasticity, stabilize the structure, and improve processability.

Double annealing

Including high-temperature and low-temperature annealing twice, and air cooling after annealing. The high temperature is 20-160°C below the beta transformation point. The low temperature is 300-500°C below the phase transition point.

Purpose: To improve organizational and performance stability.

Isothermal annealing

A special form of double annealing

First heated to 20-160 ℃ below the β transformation point. After holding, transfer to a low-temperature furnace (600-650℃) for holding. Then air-cooled to room temperature.

It is suitable for titanium alloys with high content of β-stabilizing elements. Use slow cooling to fully decompose the β phase.

Purpose: To get stable tissue.

α titanium alloys and stabilized β titanium alloys cannot be strengthened by heat treatment. Only annealed in production. α+β titanium alloys and metastable β titanium alloys containing a small amount of α phase can be further strengthened by solution treatment and aging.

Solid Solution treatment

Above the transition temperature of the α+β two-phase region. Heating at 28-83°C below the β transformation point. Special cases can also be heated above the beta transformation point, followed by quenching.

Purpose: To get a metastable β phase enhanced by a high proportion of aging.

Aging treatment

Generally heated between 425-650 ℃. The aging temperature and aging time can be determined according to the aging hardening curve.

Purpose: to promote the decomposition or precipitation of the metastable β phase, thereby improving the alloy strength.

For more titanium alloys heat treatment knowledge or titanium alloys product inquiries, contact us freely! JC Casting can provide titanium alloy casting parts, and titanium alloys CNC parts for you!

We will post the titanium alloy heat treatment standard for reference. Kindly save and check it! If you have more questions, welcome contact us: info@jccasting.com