Brass Valve Manufacturer – JC Casting

JC Casting is a professional brass valve manufacturer with investment casting foudnry and sand casting foundry. We provide high-quality valve casting solutions to customers around the world. We have 20 years of industry experience. We are both a manufacturer and a direct factory supplier. This ensure you can get the most competitive prices and the most reliable product quality.

Advantages of brass valves

1. Excellent corrosion resistance

Brass has excellent corrosion resistance. It is not easy to rust or oxidize after long-term use. It can effectively extend the life of the valve.

2. High strength and durability

Brass has excellent mechanical properties. High pressure resistance. Wear resistance. Suitable for frequent opening and closing conditions.

3. Good sealing performance

Precision machined brass valves have excellent sealing properties. Suitable for demanding fluid control systems.

4. Antibacterial properties (suitable for drinking water systems)

Brass naturally has antibacterial properties. Meets drinking water hygiene standards. Widely used in household water supply, HVAC and medical equipment piping systems.

5. High temperature and frost resistance

Wide operating temperature range (-20°C to 200°C). It can still maintain performance in extreme environments. Suitable for alternating hot and cold water or outdoor installation.

6. Economical and practical

Compared with materials such as stainless steel, brass valves are more cost-effective. Reduce procurement costs while ensuring performance.

JC’s Brass Valve Product Series

– Ball valve: DN15-DN100. Working pressure 1.6MPa. Suitable for water, oil, gas and other media.

– Gate valve: Various specifications are available. Strong corrosion resistance. Long service life

– Check valve: Prevent medium backflow. Ensure system safety.

– Angle valve: Save installation space. Easy to operate.

Why choose JC Casting as your brass valve manufacturer?

- Professional manufacturer: We have advanced casting production lines and two independent production bases. We can control the whole process from raw materials to finished products.

- Advanced technology: We use precision casting technology and CNC processing. Ensure that each valve is accurate in size and has excellent sealing performance

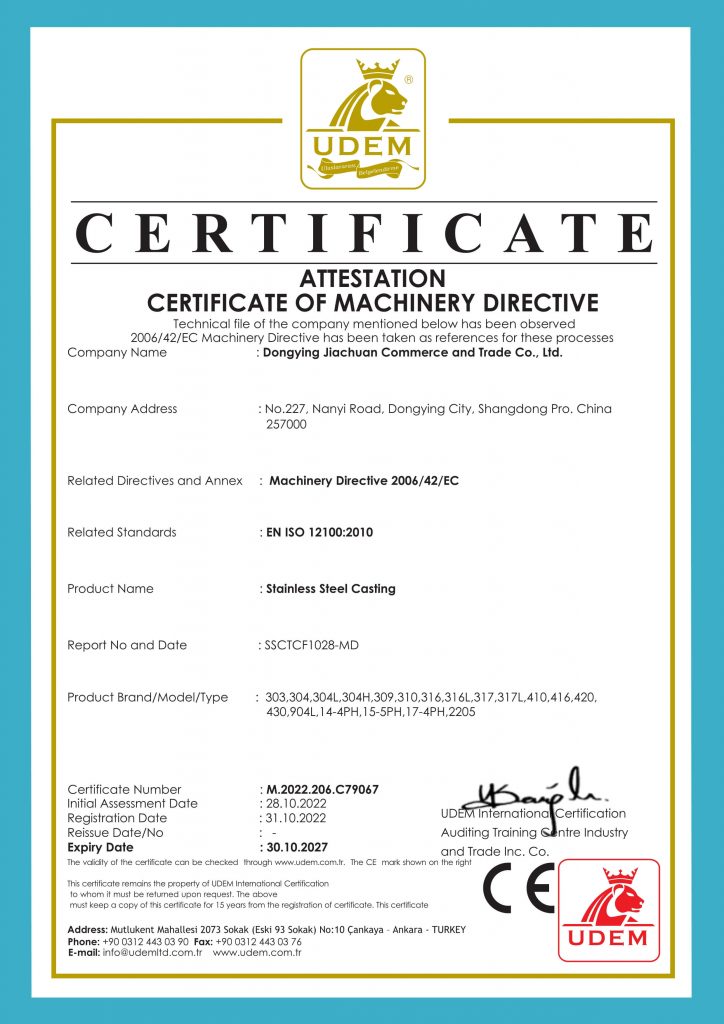

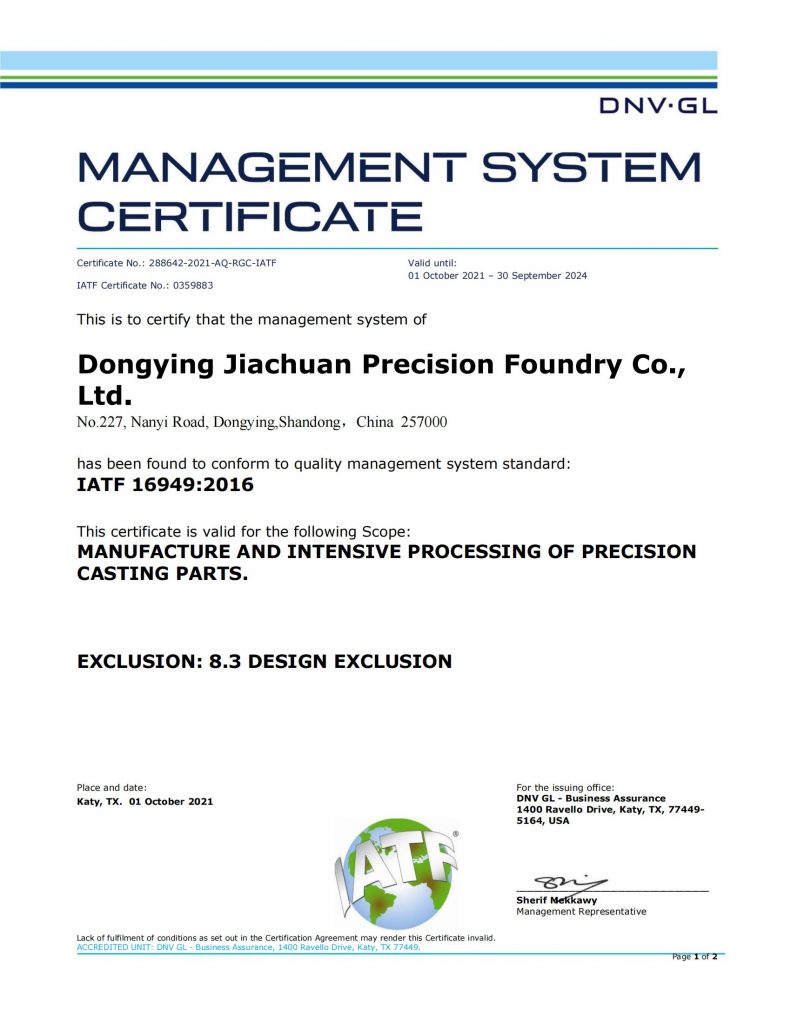

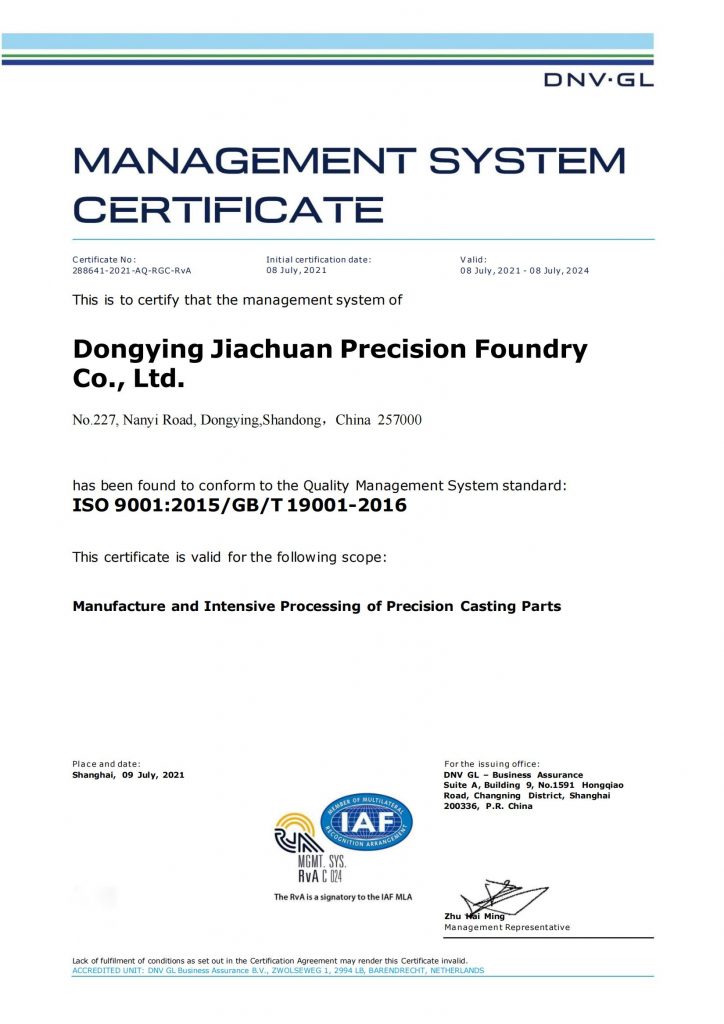

- Strict quality inspection: Passed ISO 9001,CE certification. Each batch of products undergoes multiple inspection processes such as pressure testing and sealing testing.

- Global experience: Products have been exported to more than 30 countries and regions including the United States, Germany, and the Middle East.

Our core advantages

– Price advantage: Factory direct supply. Eliminate the middle link. – Fast delivery: Regular products are delivered in 7-15 days. Customization is supported. – Technical support: Provide professional selection suggestions and installation guidance. – After-sales service: 18 months quality assurance. Quick response to customer needs.

JC Casting Production Process

Brass valves are mainly produced by two production processes: investment casting and sand casting.

Comparison of the advantages of the two processes

1. Advantages of investment casting for brass valves:

- High precision: Directly mold complex flow channels and threaded structures. Reduce CNC processing.

- Smooth surface: Reduce medium flow resistance. Suitable for sanitary applications (such as drinking water valves)

- High material utilization: scrap rate <5%. Suitable for high-cost brass raw materials.

- Batch consistency: Suitable for standardized production (such as API, EN standard valves)

2. Advantages of sand casting for brass valves:

- Low cost: Simple mold making. Suitable for small batches or large size valves (DN150 and above)

- Fast delivery: Short cycle from design to production

- Flexibility: Easy to modify the mold. Suitable for customized non-standard products.

JC Casting’s process selection strategy

- Investment casting: used for high-end ball valves, angle valves and other products with strict sealing requirements

- Sand casting: used for conventional products with simple structures such as gate valves and stop valves

- Mixed application: valve body precision casting + valve cover sand casting, balancing cost and performance

- Extra quality control

- Precision casting products: 100% X-ray flaw detection for internal pores

- Sand casting products: Add shot blasting cleaning process. Ensure that there are no sand holes on the surface

Quality Certification and Customer Cases

– Passed ISO 9001, CE and other international certifications. – Long-term supply for many internationally renowned companies. – Successfully completed the valve supply for a large water treatment project in xx country.

If you have any valve casting project, welcome contact JC Casting.We can be your reliable Brass Valve Manufacturer and partner.