Casting Processes – Types, Steps & How to Choose

Metal casting is a critical manufacturing process in which molten metal is poured into molds, allowed to solidify, and then removed to form functional components. From complex precision parts to large structural castings, understanding different casting processes helps engineers, designers, and buyers make informed decisions to optimize performance, cost, and production efficiency.

At JC Casting, a leading casting manufacturer in China, we offer a comprehensive range of metal casting processes tailored to meet a wide variety of materials and industrial applications. With advanced technologies and engineering expertise, we ensure high-quality, reliable results for every project. We provide five main casting manufacturing methods: investment casting (including Silica Sol lost wax and water glass investment casting), sand casting, die casting, and CNC machining, allowing us to deliver precise and cost-effective solutions for diverse customer needs.

What Is a Casting Process?

A casting process is the method by which liquid metal is shaped into a final part by pouring it into a mold. The process can vary widely depending on factors such as:

- Material type (stainless steel, aluminum, alloy steel, bronze, etc.)

- Part size and complexity

- Production volume

- Required tolerances and surface finish

Understanding the differences among casting processes is crucial for achieving the desired quality, durability, and cost-effectiveness.

Why Casting Processes Is Important in Manufacturing?

Metal casting offers several advantages that make it an essential step in modern manufacturing:

- Ability to produce complex geometries with minimal machining

- High strength and durability for structural and functional parts

- Flexibility in material selection and alloy composition

- Cost efficiency for both low-volume prototypes and high-volume production

Choosing the wrong casting process can lead to defects, wasted material, increased costs, and delayed production. That is why evaluating the appropriate process for each application is critical.

Types of Casting Processes in JC Casting

Different casting methods are optimized for different applications. At JC CASTING, we specialize in the following processes:

1. Investment Casting (Lost Wax Casting)

Investment casting,also called lost wax casting, is a very old manufacturing method. It refers to the general term for the process of obtaining precise size casting. Its products are precise, complex and close to the final shape of parts.It reduces material waste and provides excellent mechanical properties. Compared to traditional sand casting, investment casting results in more accurate casting size and better surface finish. It includes wax mold casting, ceramic mold casting, metal mold casting, and so on. They can be used directly with little or no post-processing.

Advantages of Investment Casting

- Superior Surface Finish

- Variety of Materials

- Complex Design,Closer to Finished Part Designs

- Tight Tolerances

- Competitive Tooling Costs

Applications of Investment Casting

- Automotive components

- Industrial equipment

- Custom structural parts

Investment Casting Types:

JC Casting can provide Silca Sol lost wax Investment casting process and water glass lost wax investment casting process.

Explore Investment Casting Solutions →

2. Sand Casting

Sand casting is also known as sand molded casting. It is a metal casting process characterized by using sand as the mold material. The sand casting part refers to an object produced by the sand casting process. Sand castings are produced in sand casting foundries.

Sand casting is a versatile and cost-effective method for producing larger components with simple or complex geometries. It supports a wide range of materials and is ideal for medium to low-volume production.

Sand casting is the most widely used metal casting method. In the market, more than 61% of all metal castings are produced via the sand casting process.

Molds made of sand are relatively cheap. It is sufficiently refractory even for steel foundry use.

Advantages of Sand Casting

- Lower costs for low-volume production runs

- Suitability for fabricating large components

- Ability to use ferrous or non-ferrous metals

- Shorter lead time compared to other processes

Applications of Sand Casting

- Heavy machinery parts

- Large structural components

- Customized industrial solutions

View Sand Casting Capabilities →

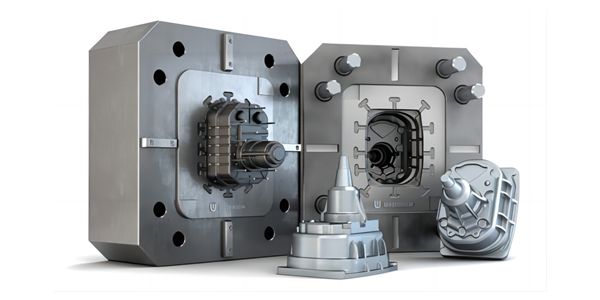

3. Die Casting

Die casting is suitable for high-volume production of non-ferrous metal components. It provides consistent quality, dimensional accuracy, and a smooth surface finish. It is characterized by the use of a mold cavity to apply high pressure to melted metal. Molds are usually machined with stronger alloys. The making of die cast parts is relatively easy, and generally requires only four major steps. They are preparation, filling, injection, and sand shakeout. Die casting has a more positive significance for aluminum alloy automobile wheels, frames and other components with higher strength impact-resistant materials.

Advantages of Die Casting

- Excellent dimensional accuracy

- Avoid secondary mechanical processing

- Fast production speed

Applications of Die Casting

- Aluminum housings

- Zinc alloy components

- High-volume consumer and industrial parts

Learn more about Die Casting →

4. CNC Machining & Secondary Processing

CNC machining definition is that it is a process of subtractive manufacturing. It uses computer and machine tools to remove layers of material from a blank or cast to produce a custom-designed part. CNC (Computerized Numerical Control) machining controls a range of complex machinery. Such as grinders, lathes, and turning mills. They are used to cut, shape, and create different parts and prototypes

The CNC process is suitable for a wide range of materials. Including metals, plastics, wood, glass, foam, and composites, and finds application in a variety of industries. Such as large CNC machining, machining of parts and prototypes for telecommunications, and CNC machining aerospace parts. They need higher tolerances than other industries. So, it is important for a manufacturer or factory to have knowledgeable CNC machinists and programmers in the industry to operate this high-tech machinery.

JC Casting has 12 sets of CNC machines and 5 engineers, 120 staff.

PS: CNC machining definition vs the CNC machine definition: One is a process and the other is a machine. CNC Machining Produces Little to No Waste

Advantages of CNC Machining

- Zero Defects and Greater Accuracy

- Faster and Efficient Production

- Complex designs available

- One operator can supervise more than one machine at a time

Secondary services include:

- CNC milling and turning

- Drilling, tapping, and threading

- Surface finishing, coating, and assembly support

To meet precise tolerances or complex geometries, CNC machining and secondary processes are integrated with our casting services. This ensures fully functional components ready for assembly.

Discover CNC Machining Services →

Comparing Casting Processes

| Process | Precision | Surface Finish | Best For | Cost |

|---|---|---|---|---|

| Silica Sol Investment | Very High | Excellent | Complex thin-wall parts | Medium |

| Investment Casting | High | Good | Intricate designs | Medium |

| Sand Casting | Medium | Average | Large/medium parts | Low |

| Die Casting | High | Very Good | High-volume production | High |

This comparison table helps engineers and procurement managers choose the optimal process for specific materials, part sizes, and production volumes.

How to Choose the Right Casting Process

When selecting a casting process, consider these factors:

- Part Geometry & Complexity – Thin walls or intricate features require precision processes like investment casting.

- Material Requirements – Some alloys are better suited for specific casting methods.

- Production Volume – High-volume runs often justify die casting; small runs may favor sand or investment casting.

- Budget & Lead Time – Consider tooling costs, post-processing needs, and production speed.

- Functional Requirements – Strength, durability, and surface finish dictate process choice.

At JC CASTING, our engineering team evaluates all these factors to recommend the most efficient and reliable solution for your project.

Why Choose JC CASTING?

- Over 20 years of precision casting experience

- Comprehensive coverage of all major casting processes

- Advanced quality control and inspection systems

- On-time delivery and production stability

- Engineering support from design consultation to finished product

We help customers across automotive, aerospace, industrial machinery, energy, and more achieve optimized parts for their applications.

Start Your Casting Project Today

Whether developing a new design or improving an existing part, JCCASTING is ready to support your project with professional casting expertise.

Contact our engineers today to discuss your requirements or upload your drawings for a free evaluation.