Impeller Casting Manufacturer for Industrial Applications

JC Casting is a professional impeller casting manufacturer and supplier in China. We specialized in high-quality metal impellers for industrial pump systems. We produce custom impeller castings using various materials, including stainless steel, carbon steel, alloy steel, cast iron, bronze, and brass, serving global OEMs and equipment manufacturers.

With advanced casting processes, strict quality control, and in-house CNC machining, JC Casting delivers dimensionally accurate, corrosion-resistant, and performance-stable impeller castings designed for demanding operating conditions.

What Is Impeller Casting?

An impeller casting is a precision metal component used in pumps to transfer energy from the motor to the fluid. Through rotation, the impeller increases fluid velocity and pressure, making it a critical part of centrifugal pumps, water pumps, chemical pumps, and industrial fluid systems.

Compared with forged or machined impellers, casting allows:

- More complex blade geometry

- Better material utilization

- Lower cost for medium and large batches

- Wider material selection

Impeller casting is widely used in industries where flow efficiency, wear resistance, and corrosion resistance are essential.

The Function of the Impeller:The main function of the impeller is to convert mechanical energy into fluid energy. For example, in a pump, the rotation of the impeller can generate centrifugal force. It sucks the fluid into the pump and accelerates it outward. Thus increasing the fluid’s speed and pressure.

The types of Impeller Casting

Different types of impeller has different features and applications. For more info, kindly check the article:

Impeller Casting Material Types

We understand that different applications need specific material properties. So, we offer a variety of materials for impeller castings.The right impeller material is crucial for the performance and longevity of the pump system.

Stainless Steel Impeller Casting

- Grades: CF8 (304), CF8M (316), 304, 316, PH 17-4, 2205 duplex stainless steel.

- Advantages: Excellent corrosion resistance, smooth surface, long service life

- Applications: Chemical pumps, food processing, marine pumps

Carbon Steel & Alloy Steel Impeller Casting

- High strength and pressure resistance

- Suitable for high-load industrial pumps

- Cost-effective for large equipment

Cast Iron & Ductile Iron Impeller Casting

- Good wear resistance

- Stable structure

- Widely used in water pumps and municipal systems

- cast iron impeller, ductile iron impeller casting

Bronze & Brass Impeller Casting

- Excellent resistance to seawater corrosion

- Good anti-sparking properties

- Common in marine and special industrial applications

- bronze impeller casting, brass impeller casting

Titanium Alloy Impeller Casting

- For high-temperature applications.

- Such as power generation turbines and aero engines.

Aluminum Impeller Casting

- light weight, high strength and good corrosion resistance.

- Reduce the load of equipment.

- Used in aerospace and automotive industries.

Marine Industry Case:A shipbuilding company’s seawater cooling system required an impeller. The impeller was made of duplex stainless steel. It can withstand the harsh marine environment. The corrosion resistance and erosion resistance of the impeller ensured long-term and reliable operation, reduced the need for frequent replacements, and minimized the ship’s downtime. The shipbuilding company was deeply impressed by the performance of the impeller and has continued to purchase impellers from us for their new ship projects ever since.

Impeller Casting Processes We Use

Choosing the right impeller casting process is critical for performance, accuracy, and cost. JC Casting provides multiple options to ensure your impeller castings meet the highest standards.

Sand Casting Impeller

- Suitable for medium and large impellers

- Flexible design

- Lower tooling cost

Silica Sol Investment Casting

- High dimensional accuracy

- Smooth surface finish

- Ideal for complex blade structures

Water Glass Investment Casting

- Cost-effective solution

- Suitable for less complex designs

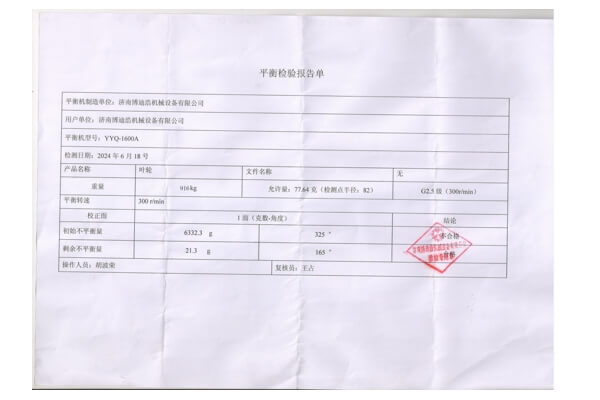

CNC Machining & Balancing

After casting, impellers can be fully machined and dynamically balanced to ensure:

- Stable rotation

- Reduced vibration

- Longer bearing life

Size Range

Our manufacturing capabilities enable us to produce impellers within a wide range of sizes. We can produce small impellers with a diameter as small as a few centimeters. They are suitable for medical equipment, small pumps, and precision machinery. We also have the expertise and equipment to handle large impellers with a diameter of more than several meters. These impellers are usually used in power plants, large industrial pumps, and marine applications.

Small Precision Case

A microfluidic pump of a laboratory equipment supplier required an impeller with a diameter of only 3 centimeters. Using our precision machining and investment casting technologies, we were able to produce an impeller with extremely small tolerances. The impeller had precise dimensions and a smooth surface, enabling it to handle fluids efficiently at the micron scale and meet the high standards of the laboratory equipment.

Large Industrial Example

A large power plant required an impeller with a diameter of 3.5 meters for their water treatment equipment.

Applications of Impeller Casting

JC Casting impeller castings are widely used across various industries:

Pump Industry

- Centrifugal pump impeller casting

- Industrial pump impeller casting

- Water pump impeller

Chemical & Process Industry

- Chemical pump impeller

- Corrosion-resistant impeller casting

Pump Industry

- Centrifugal pump impeller casting

- Industrial pump impeller casting

- Water pump impeller

Marine Industry

- Marine impeller casting

- Seawater pump impeller

Mining & Slurry Handling

- Slurry pump impeller casting

- Wear-resistant impeller

- centrifugal pump impeller casting

Key Advantages of JC Casting Impeller Castings

1. Stable Quality & Precision Control

- Strict chemical composition control

- Dimensional tolerance inspection

- Consistent batch quality

2. Material Selection Based on Real Working Conditions

We help customers choose impeller materials based on:

- Fluid type

- Temperature

- Pressure

- Corrosion and wear requirements

3. Custom Impeller Casting Service

- OEM impeller casting

- Custom size and design

- Production based on drawings or samples

- Keywords: custom impeller casting, OEM impeller casting

4. Integrated Manufacturing Capability

From casting to machining and inspection, all processes are controlled in-house:

- Casting

- Heat treatment

- CNC machining

- Balancing

- Final inspection

Common Impeller Casting Defects and How We Control Them

Typical defects in impeller casting include:

- Porosity

- Shrinkage

- Imbalance

- Dimensional deviation

JC Casting controls these risks through:

- Optimized gating and riser design

- Simulation-based mold design

- Strict process monitoring

- 100% dimensional check on key features

Quality Control & Inspection

Each impeller casting undergoes multiple inspections:

- Chemical composition analysis

- Mechanical property testing

- Dimensional measurement

- Surface defect inspection

Inspection reports can be provided upon request.

impeller casting balance testing

impeller casting balance testing impeller casting chemical compositon testing

impeller casting chemical compositon testing impeller casting dimension testing

impeller casting dimension testing

Here is JC Impeller Casting Process. You can download it!

Why Choose JC Casting as Your Impeller Casting Supplier?

- ✔ Experienced impeller casting manufacturer

- ✔ Multiple material and process options

- ✔ OEM and custom production support

- ✔ Stable export quality

- ✔ Technical communication with engineers

We are not just a supplier, but a long-term manufacturing partner.

Impeller Casting FAQs

Do you provide machining and balancing?

What industries do you mainly serve?

What is the minimum order quantity?

What are the four types of casting?

What is the purpose of an impeler?

Get a Quote for Custom Impeller Casting

If you are looking for a reliable impeller casting manufacturer or supplier, JC Casting is ready to support your project. Send us your drawings, material requirements, and application details. Our engineering team will provide a professional solution and competitive quotation. Buy impeller casting online or get in touch with us for OEM impeller casting in China!