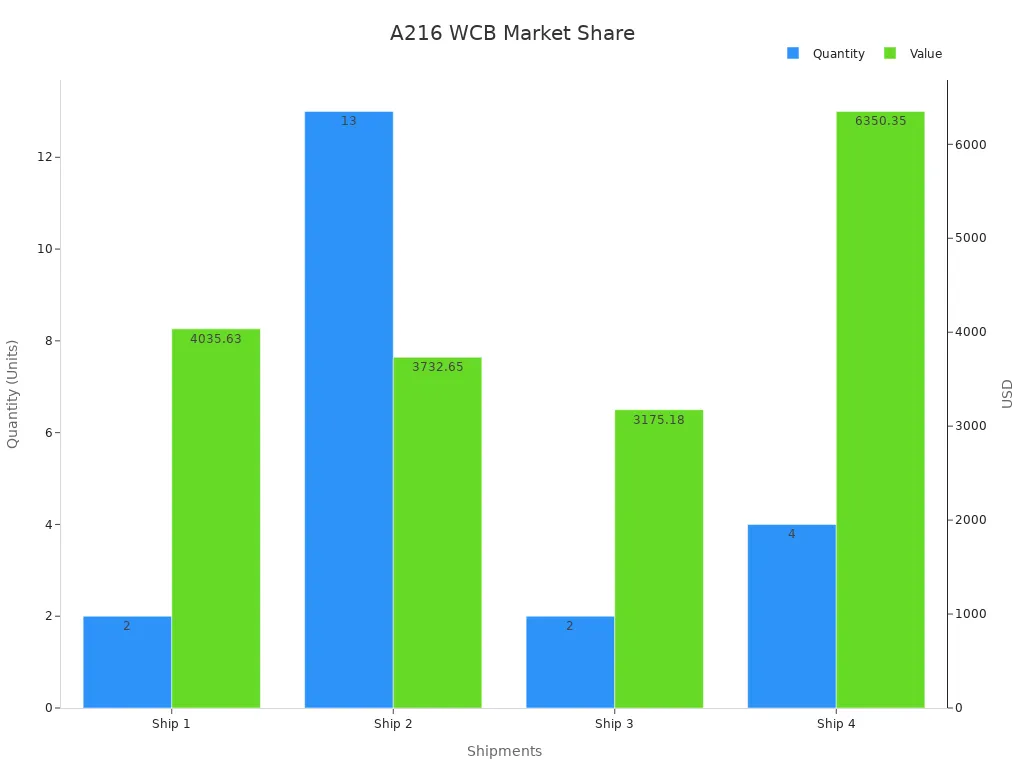

How A216 WCB Powers Industrial Valve Applications

Choosing the right material helps valves work well and last long. A216 WCB is a top pick for important valve parts. It is used for bodies, discs, and bonnets in valves. Manufacturers trust A216 WCB for tough places and hard jobs. ASTM A216 WCB gate valves are shipped often to big markets.

A216 WCB is used a lot in factories. This shows it works well in real-life situations.

Key Takeaways

- A216 WCB is a strong carbon steel.

- It is used to make valve parts in many industries.

- This steel can handle high pressure and heat up to 800°F.

- It works well for oil, gas, and power plant valves.

- A216 WCB is easy to weld.

- This helps people build and fix valves quickly and cheaply.

- Valves made from A216 WCB last a long time.

- They do not wear out fast and save money on repairs.

- But, A216 WCB is not good for very cold or very rusty places.

- Always check if this steel fits your needs before using it.

What Is A216 WCB?

Material Overview

A216 WCB is a type of carbon steel. It is often used to make valve bodies and parts. This steel follows the ASTM A216 standard for hot places. Manufacturers pick A216 WCB because it is strong and tough. It is also easy to work with in factories. “WCB” stands for “Wrought Carbon grade B.” This tells us about its chemical makeup and strength.

Scientists study A216 WCB to learn about its makeup.

Adding chromium and tungsten carbide (WC) makes it better. Copper chills during casting help make the steel stronger. This process also lowers holes in the metal. The table below shows what studies have found:

| Aspect | Summary |

|---|---|

| Composition | Carbon steel with 0.5% chromium; WC particles added up to 15% by weight |

| Microstructural Refinement | Copper chills create fine pearlite and more carbides, reducing porosity and improving uniformity |

| Mechanical Properties | Tensile strength rises from ~258 MPa to ~489 MPa at 12% WC; hardness increases from 79 HRC to 132 HRC |

| Wear and Tribological Behavior | Wear resistance improves with more WC; friction and weight loss decrease; mild wear appears sooner |

Key Features

A216 WCB has many good qualities for valves:

- High Strength: It can handle high pressure and force.

- Good Hardness: It protects valve parts from damage.

- Improved Wear Resistance: It lasts longer and reduces friction.

- Consistent Quality: Copper chills make the steel even and strong.

- Versatility: A216 WCB works for many valve types and sizes.

Note: A216 WCB is strong and tough. But, check if it fits your needs for rust and heat.

Why Pick A216 WCB

Mechanical Strength

A216 WCB is known for being very strong.

It can take a lot of pressure and force.

This makes it a good choice for valves in factories.

Engineers use it for parts that must not bend or break.

| Property | Condition | Test Temp | Value (Metric) | Value (Imperial) |

|---|---|---|---|---|

| Tensile Strength | Annealed | Room Temp | 370 – 490 MPa | 54 – 71 ksi |

| Yield Strength | Annealed | Room Temp | 205 – 310 MPa | 30 – 45 ksi |

| Elongation | Annealed | Room Temp | 20 – 30% | 20 – 30% |

| Hardness (Brinell) | Annealed | Room Temp | 130 – 200 HB | 130 – 200 HB |

| Impact Strength | Charpy V | -20°C | 27 – 40 J | 20 – 30 ft-lbf |

A216 WCB is both strong and bendy.

It can stretch before it breaks.

It can also take hits without breaking.

This keeps people safe when using pipes and tanks.

It passes tough ASTM tests for quality.

A216 WCB is not too costly for its strength.

A105 is stronger but costs more and is for small valves.

LCB is better for cold but is not used as much.

Temperature Range

A216 WCB works in hot and cold places.

It stays strong up to 425°C (800°F).

This is good for steam, oil, and gas pipes.

For very cold jobs, LCB is a better pick.

| Material Grade | Max Temp | Min Temp | Use Case |

|---|---|---|---|

| A216 WCB | 425°C (800°F) | -29°C (-20°F) | Most jobs, medium pressure |

| LCB | 345°C (650°F) | -46°C (-50°F) | Cold jobs |

| A105 | 538°C (1000°F) | -29°C (-20°F) | Small, high-pressure valves |

A216 WCB fits most factory needs.

It works well without costing too much.

Tip: For very hot or cold jobs, check what you need first.

Weldability

Weldability means parts can be joined easily.

A216 WCB is easy to weld for making and fixing valves.

The “W” in WCB means it is weldable.

Valve makers use many tests to check welds:

- RT finds hidden problems in welds.

- MT or PT finds cracks on the surface.

- 100% RT on samples keeps parts safe.

- Other tests check strength and toughness after welding.

- Checks make sure the steel is right.

- All welds must pass ASME and ASTM rules.

These steps help keep A216 WCB valves safe and strong.

A105 welds well but is hard to cast big.

LCB welds well but is for cold jobs.

Note: Easy welding saves money and time when making valves.

In summary:

A216 WCB is strong, works in many temperatures, and is easy to weld.

It is good for many factory jobs, especially big valves.

If you want safety, low cost, and easy making, A216 WCB is a great choice.

A216 WCB Valve Applications

Gate Valves

Gate valves help control liquids and gases in pipes.

A216 WCB is picked for these valves because it is strong.

Big gate valves in power plants need to handle high pressure.

They also need to work in hot places.

Here is a table with facts about a 20-inch gate valve:

| Property/Specification | Value/Range |

|---|---|

| Torque Value | 2850 N.m |

| Turns to Open | 60 |

| Valve Size (20 Inch, Class 300) | End to End: 991-1010 mm |

| Weight | 1625-1938 Kg |

| Density | 7.82 g/cm³ (488 lb/ft³) |

| Young’s Modulus | 210 GPa (30 x 10⁶ psi) |

| Elongation at Break | 25% |

| Tensile Strength Ultimate (UTS) | 570 MPa (83,000 psi) |

| Tensile Strength Yield (Proof) | 280 MPa (41,000 psi) |

| Thermal Expansion | 11.9 µm/m-K |

| Service Temperature Range | -30°C to +425°C (-20°F to +800°F) |

| Specific Heat Capacity | 450 J/kg-K |

| Strength to Weight Ratio | 73 kN-m/kg |

| Max Service Temperature | 500°C |

| Melting Point | 1380 – 1514°C |

Valve makers use A216 WCB for the main parts.

They use other strong metals for the stem and seat ring.

This mix helps the valve last longer and stay safe.

- Body: ASTM A216 Grade WCB

- Wedge: ASTM A216 Grade WCB with 13% Chromium Steel

- Bonnet: ASTM A216 Grade WCB

- Packing: Graphite with braided end rings

Gate valves made from A216 WCB can take high force.

They also do not wear out fast or break from heat.

Globe Valves

Globe valves help control flow more exactly.

Many factories use globe valves made from A216 WCB.

This steel is strong and can bend without breaking.

It also fights rust better than some other steels.

- Engineers pick this steel for globe valves for its strength.

- It is easy to weld and fix if needed.

- Globe valves with this steel work well in many places.

- The steel can be used in many jobs, like power plants.

Globe valves made from A216 WCB are strong and not too costly.

Check Valves

Check valves stop flow from going backward in pipes.

A216 WCB is a good choice for these valves.

It is strong, easy to weld, and not too expensive.

Here is a table comparing A216 WCB and WCC:

| Property | ASTM A216 WCB | ASTM A216 WCC |

|---|---|---|

| Carbon | Up to 0.30% | Up to 0.25% |

| Manganese | Up to 1.00% | Up to 1.20% |

| Silicon | Up to 0.60% | Up to 0.60% |

| Sulfur | Up to 0.035% | Up to 0.035% |

| Phosphorus | Up to 0.035% | Up to 0.035% |

| Residual Elements | Up to 1.00% | Up to 1.00% |

| Tensile Strength | 70 to 95 ksi | 70 to 95 ksi |

| Yield Strength | 36 ksi | 40 ksi |

| Elongation (2 in) | Minimum 22% | Minimum 22% |

| Reduction of Area | Minimum 35% | Minimum 35% |

A216 WCB check valves work well in most factories.

They are strong and do not rust too fast.

WCC is a bit stronger but costs more.

Many engineers like A216 WCB for its good value.

Ball Valves

Ball valves use a ball to start or stop flow.

Factories use these valves for quick shut-off.

A216 WCB makes ball valves strong for high pressure.

It is easy to weld, so big ball valves can be made.

These valves are used in oil, gas, and power plants.

- Ball valves with this steel do not wear out fast.

- The steel helps the valve keep its shape under stress.

- With care, these valves can last many years.

Ball valves made from A216 WCB work well in hard jobs.

Other Valves

A216 WCB is also used in other valve types.

These include plug valves, pressure seal valves, and special valves.

These valves need strong steel that can be welded.

A216 WCB is a good pick for big or custom valves.

- Plug valves use this steel because it is tough.

- Pressure seal valves need its strength for tight seals.

- Special valves use it for its good price and strength.

Many companies trust A216 WCB for many valve types. Its features help keep systems safe and working well.

A216 WCB in Fittings

Flanges

Flanges join pipes and valves in factories.

Engineers pick strong flanges to stop leaks.

ASME made new rules in 2019 for flange castings.

Now, flanges are put in Curve B or C by thickness.

If a flange is 2 inches thick or less, it needs heat treatment.

This means heating and cooling the metal in water.

This helps flanges stay safe in cold places.

It also stops them from breaking easily.

The new rules let some flanges work in colder spots.

They raised the lowest safe temperature by 38°F.

No extra impact tests are needed for these.

Grain size and what is in the metal must be checked.

Extra rules like S15 and S52.1 keep flanges strong.

These rules help flanges work during starts, stops, and tests.

All these steps show how flanges should work in real jobs.

Tees and Elbows

Tees and elbows help pipes turn or split.

Factories use them where pipes change direction.

The steel must take high pressure and fast flow changes.

Strong steel tees and elbows do not bend or crack.

They keep their shape when systems start or stop fast.

Many companies use these because they last long.

They are also easy to put in place.

The inside is smooth, so things flow easily.

Reducers and Custom Fittings

Reducers join pipes of different sizes.

Custom fittings fix special pipe problems.

Both types must fit tight and be strong.

Good steel helps them hold heavy loads and pressure.

Custom fittings may need special shapes or sizes.

Factories can shape this steel for many uses.

These fittings help keep systems safe and working well.

Industry Use and Benefits

Sectors

Many industries need strong valves that last a long time.

A216 WCB is used in many important jobs.

Oil and gas companies use it for most of their valves.

It is common in pipelines that move oil and gas.

Chemical plants and power plants also use this steel.

Cities use it for water pipes and pumps.

A216 WCB is picked because it is tough and easy to weld.

It can handle high pressure and heat without breaking.

Look at the table to see how it compares to other metals:

| Property/Criteria | WCB Carbon Steel | Stainless Steel (CF8M) | Ductile Iron | Forged Carbon Steel (A105) |

|---|---|---|---|---|

| Corrosion Resistance | Moderate | Excellent | Moderate | Moderate |

| Tensile Strength (MPa) | 485–655 | 485–620 | 450–550 | 485–620 |

| Weldability | Excellent | Good | Moderate | Excellent |

| Cost Level | Low to Moderate | High | Low | Moderate to High |

| Application Suitability | General valves, pumps, pressure parts | Chemical, food, marine | Municipal, low-pressure piping | High-pressure flanges, power equipment |

Many factories trust A216 WCB because it is strong and not too costly.

Durability and Cost

A216 WCB lasts a long time and saves money.

Many companies want valves made from this steel.

These valves do not wear out fast and are easy to fix.

In oil and gas, they work hard and help make more products.

Here are some real examples:

- Fixing a big valve saved 65% in costs and lasted 8 years.

- Repair time dropped from 16 weeks to 3 weeks, saving $1.8 million.

- In a refinery, seals lasted 5 years instead of 6 months, saving $1.2 million each year.

These facts show A216 WCB valves help save money.

They also make repairs faster and easier.

Limitations

A216 WCB works best with water, oil, and gas.

It can be used from -20°F to 800°F.

But it does not fight rust as well as stainless steel.

In places with CO2 or H2S, it can rust or break.

It is not good for very cold or very harsh places.

For those jobs, engineers use other types of steel.

Tip: Always check what will flow through the valve and the temperature before picking A216 WCB.

Engineers use this steel to make strong, low-cost valves.

Many companies trust it because it is safe and lasts long.

It is strong, easy to weld, and works in hot or cold.

These valves need less fixing, so companies save money.

As factories get bigger, this steel will stay important for valves.

FAQ

What does “WCB” mean in A216 WCB?

“WCB” means “Wrought Carbon grade B.”

This tells us what kind of steel it is.

It also shows how strong the steel is.

Factories use it for valve parts and pipe pieces.

It meets tough rules for making valves.

Can A216 WCB handle corrosive fluids?

A216 WCB can stop some rust.

It works well with water, oil, and gas.

For strong acids or salty water, use stainless steel.

Special metals are better for harsh chemicals.

Is A216 WCB suitable for cryogenic service?

A216 WCB is not good for very cold jobs.

It does not stay strong in freezing places.

For cold work, engineers pick LCB or other steels.

These steels stay safe and tough in the cold.

How does A216 WCB compare to stainless steel?

A216 WCB costs less than stainless steel.

It is strong and easy to weld.

Stainless steel fights rust better.

It works in rougher places but costs more.

What industries use A216 WCB valves most?

Oil and gas companies use A216 WCB valves a lot.

Chemical plants and power plants use them too.

Water treatment plants also use these valves.

These places need strong and low-cost valves.