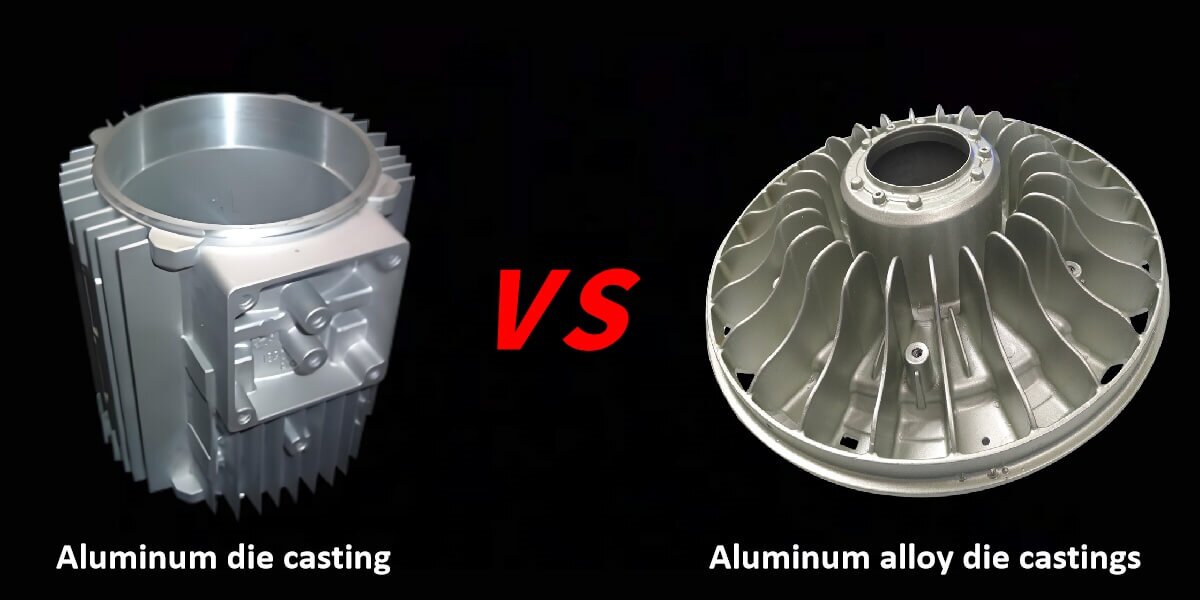

Aluminum die casting and aluminum alloy die casting are both important processes for producing aluminum parts. There is only a word difference. But in the nature of the material, performance performance, application scenarios and cost control aspects have significant differences. What is the difference and connection between the two processes? And how to choose according to the needs? Let’s explore Aluminum Die Casting VS Aluminum Alloy Die Casting !

The following are the similarities between aluminum die casting and aluminum alloy die casting

Basic Principle

Both are die casting processes. The liquid or semi-liquid aluminum or aluminum alloy material is rapidly filled into the cavity of the die casting mold under high pressure. Then, it is cooled and solidified under pressure to form the product.

Production Equipment

Both require key equipment. Such as die casting machines and die casting molds.

Forming Characteristics

Both can produce parts with relatively high dimensional accuracy and good surface quality.

Application Industries

Products of both aluminum die casting and aluminum alloy die casting are widely used in many industries. For example, in the electronic and electrical industry. They are used to manufacture various casings, radiators. In the field of mechanical manufacturing, they are used to produce the casings, brackets. In the daily necessities industry, they are used to manufacture some decorative or functional parts.

Post-processing

After forming, both usually need some post-processing procedures. Such as deburring, surface cleaning, heat treatment, and surface coating .

The following are the differences: aluminum die casting vs aluminum alloy die casting

· Products of Aluminum Alloy Die Casting

Because alloy elements are added, aluminum alloy die-cast products are usually much stronger and harder than pure aluminum die-cast products. They can withstand greater external forces and more complex usage environments. At the same time, according to different alloy compositions, they can also have special properties. Such as good corrosion resistance and heat resistance.

Application Fields

· Aluminum Die Casting

It is mainly applied to some fields where the purity requirement of the material is relatively high and the strength requirement is relatively low. For example, some radiator components in the electronic and electrical field. It needs the good thermal conductivity of pure aluminum to dissipate heat quickly. There are also some decorative products and handicrafts.

· Aluminum Alloy Die Casting

It is widely used in the fields of automobile and motorcycle manufacturing. For example, components such as engine blocks, cylinder heads, transmission cases, and wheels. These components require high strength and corrosion resistance to ensure the safety performance and service life of the vehicles. In the aerospace , some aluminum alloy die-cast parts are also used to manufacture aircraft structural components, engine parts. To reduce the weight of the aircraft and ensure the structural strength. In addition, in the 3C electronics field. Such as the casings of mobile phones and laptops, the aluminum alloy die casting process is often used to get lightweight, strong, and casings with good heat dissipation performance. For example, the casings of Apple laptops.

Production Cost

· Aluminum Die Casting

The price of pure aluminum material is relatively low. The production process is relatively simple. Therefore, it has certain advantages in some cost-sensitive application scenarios.

· Aluminum Alloy Die Casting

Because the composition of aluminum alloy is rather complicated, it is essential to accurately control the alloy composition throughout the production process. The different aluminum alloys may require the use of different die casting process parameters. So the production cost is usually higher than that of aluminum die casting. However, its performance advantages make it widely used in many high-end product fields. Even though the cost is high, it still has a relatively high cost performance.

Aluminum Casting Foundry

JC Casting specializes in the production and manufacturing of aluminum castings. By taking advanced casting processes. Such as sand casting and die casting. It can produce a wide variety of products. Including automotive parts, mechanical components, and electronic device housings. With a professional technical team, it ensures the precision, strength, and surface quality of the products, providing reliable aluminum casting solutions for various industries.

If you are looking for a trustworthy partner, JC Casting will be a great choice for you. You are welcome to send your inquiries to us at info@jccasting.com.