As a company with 20 years of professional valve casting experience, JC Casting is well aware of the key role of valves in industrial systems. Valves are important devices for controlling fluid flow and are widely used in many fields. Such as petroleum, chemical industry, electric power, water treatment. Here, we will introduce Everything you want to know, from types of vavle and functions to material selection guidelines.A comprehensive breakdown of Types of Valves: what they are and how they work.

Definition of valve

A valve is a mechanical device that controls the flow of fluid by opening, closing or partially blocking a passage. Valves are everywhere, from household taps to control devices in industrial piping systems. The basic functions of valves include:

- – Opening and closing fluid flow

- – Regulating flow rate

- – Preventing backflow

- – Regulating system pressure

- – Separating or mixing different fluids

Function of valves

Flow control: Valves can accurately adjust fluid flow to meet different process requirements. For example, in chemical production, regulating valves are needed to strictly control the amount of reactants added.

Pressure regulation: Safety valves and pressure reducing valves can prevent system pressure from being too high. Protect equipment and personnel safety. When the pipeline pressure exceeds the set value, the safety valve will automatically open to release pressure.

Flow control: Check valves can ensure one-way flow of fluid. Prevent backflow from causing pollution or equipment damage. This is especially important in the outlet pipeline of the pump.

System isolation: In maintenance or emergency situations, closing valves can quickly cut off the fluid. Create conditions for maintenance work. For example, when a pipeline leaks, quickly closing upstream and downstream valves can minimize losses.

Media separation: Specially designed valves can separate different media to prevent mixing. This is common in multi-product pipeline transportation systems.

Safety protection: In addition to pressure protection, some valves also have functions such as temperature protection and liquid level control. Comprehensively guarantee the safe operation of the system.

Types of Valves and Typical Product Introduction

There are many types of valves.Such as Gate valve,Ball valve,Check valve,Safety valve,Stop Valve/ Globe Valve. Here are the main types brief intruduction and their characteristics:

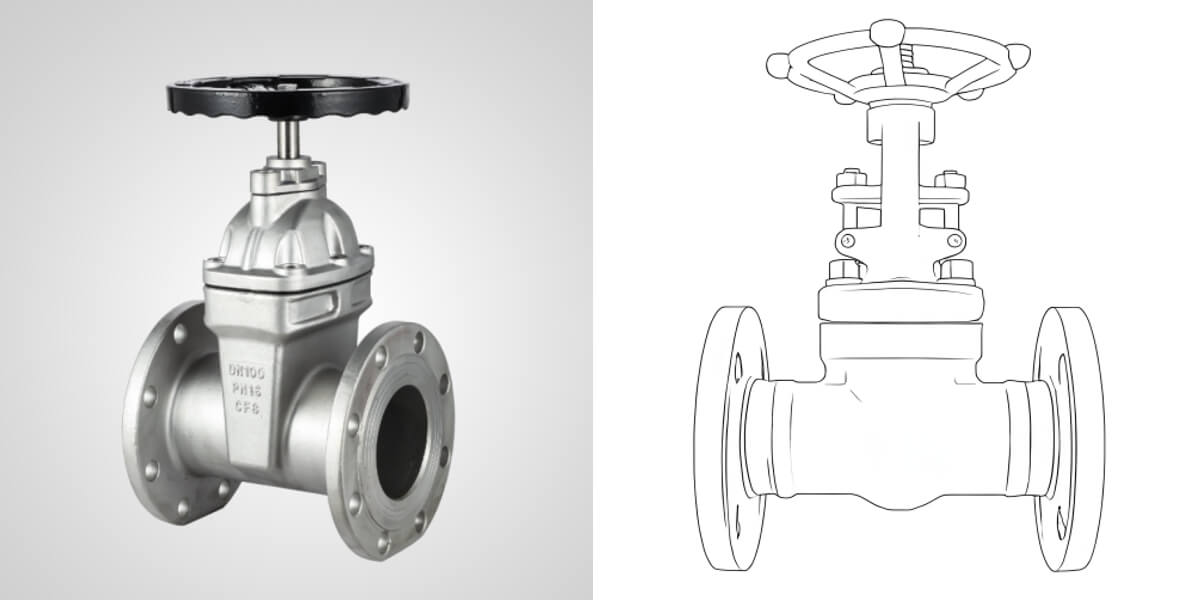

Gate valve

Gate valve is one of the most common valve types. Its characteristics are:

- Small flow resistance. Suitable for large flow occasions

- Not suitable for regulating flow

- Good sealing performance

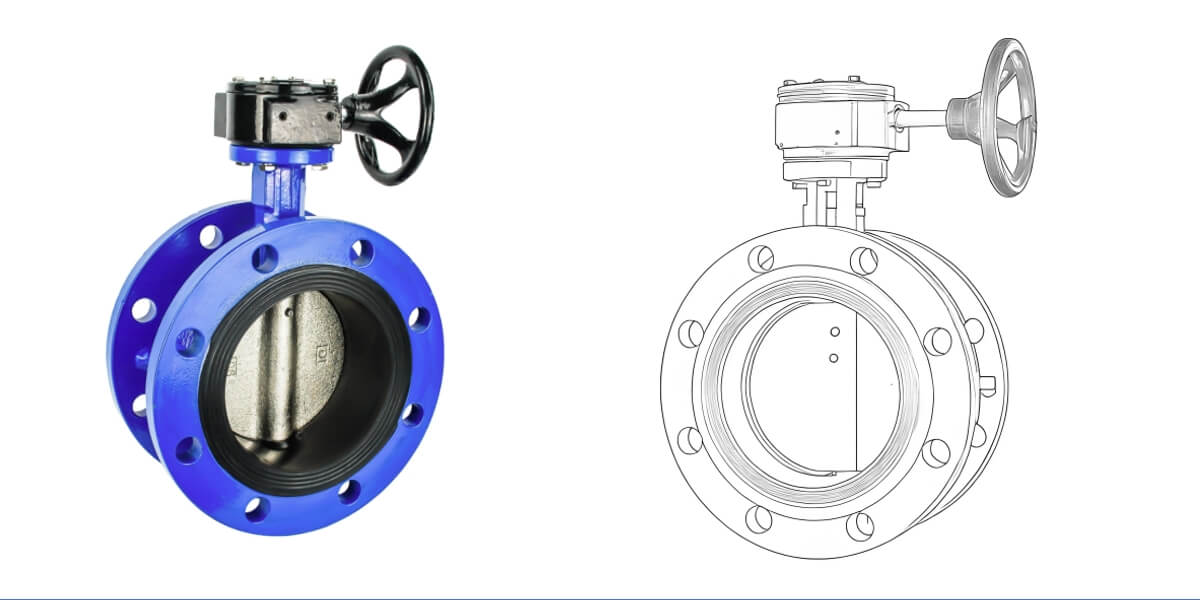

Butterfly valve

Controls flow by rotating a disc-shaped valve disc. The structure is simple and compact. Its features are:

- – Small size and light weight

- – Suitable for large pipe diameters

- – Good regulation performance

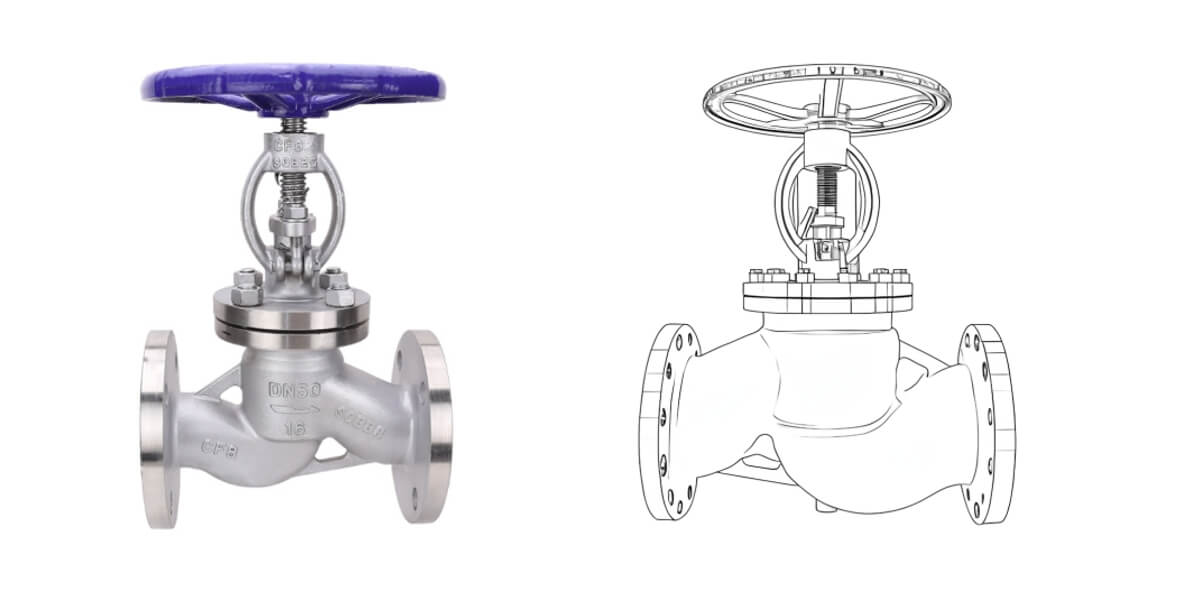

Stop valve

The stop valve controls the flow rate by the lifting and lowering movement of the valve disc. It has good regulation performance. Features include:

- – High regulation accuracy

- – Low wear on the sealing surface

- – Large flow resistance

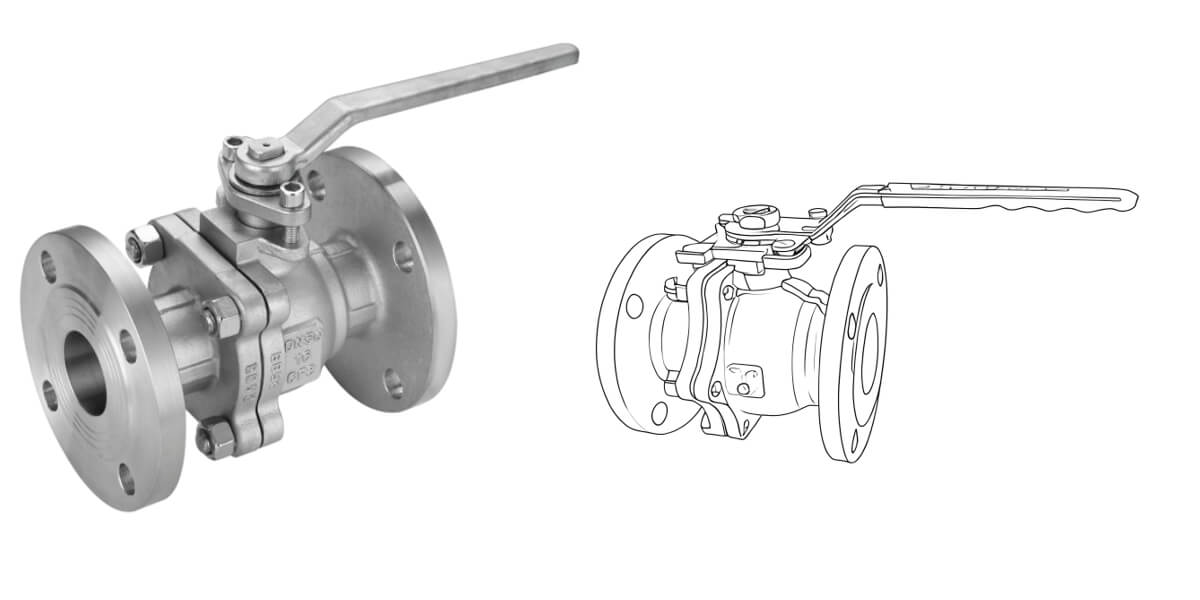

Ball valve

Rotate the handle 90 degrees to fully open or close. Features include:

- – Easy to operate. Quick opening and closing

- – Low fluid resistance

- – Suitable for high pressure and high cleanliness occasions

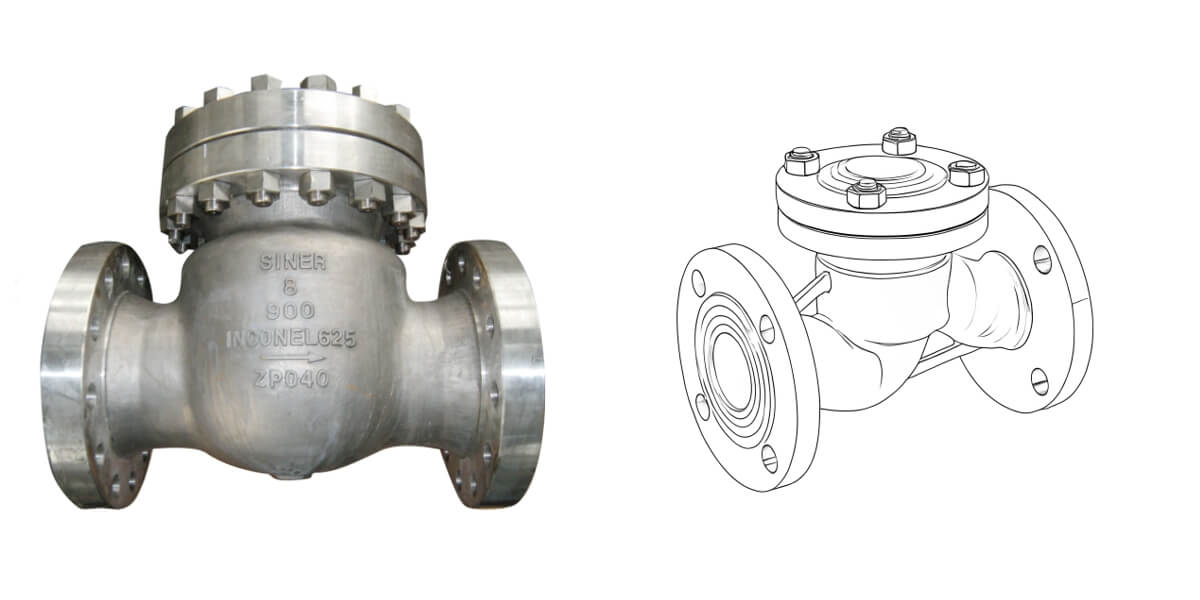

Check valve

Check valve is also called one-way valve. It only allows fluid to flow in one direction. Its features are:

- – Automatic operation without external force

- – Prevent medium from flowing back

- – Protect pumps and other equipment

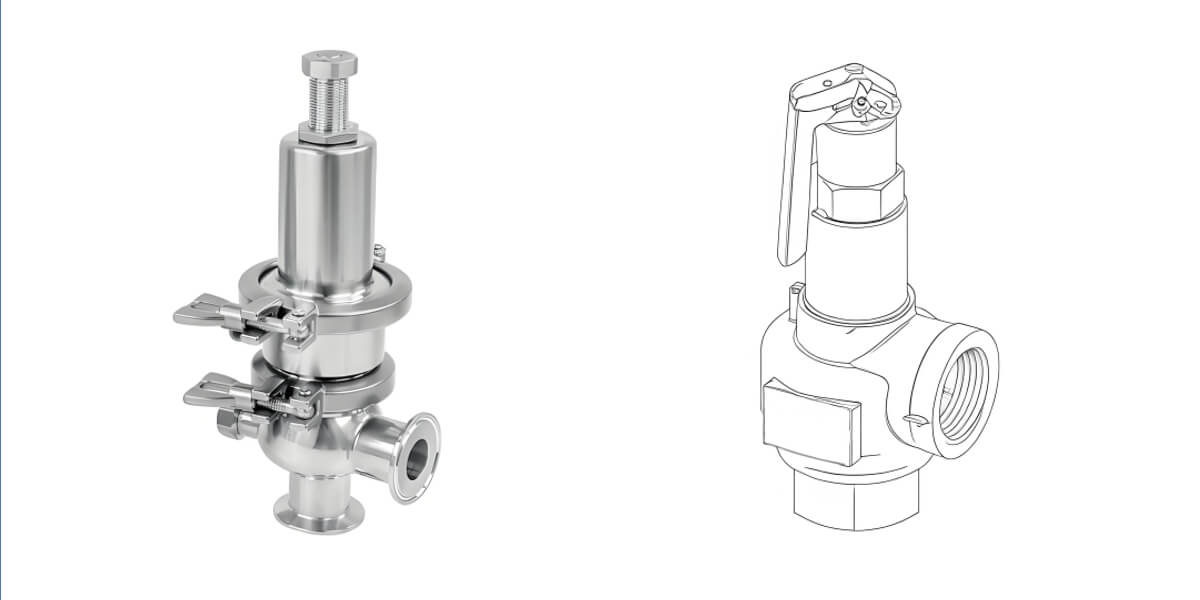

Safety valve

Safety valve is an important safety protection device. It automatically opens to release pressure when the system pressure exceeds the set value. Features:

- – Accurate pressure setting

- – Quick response

- – Must be calibrated regularly

Material selection of valves

Valve materials directly affect their performance, life and scope of application. JC Casting’s rich experience can provide customers with professional material selection suggestions:

Cast iron valves

– Applicable occasions: low-pressure, normal temperature water, air, steam and other non-corrosive media

– Typical materials: HT200, QT400

Cast steel valves

– Applicable occasions: medium-high pressure, high temperature conditions, such as power stations, petrochemicals

– Typical materials: WCB, WCC, LCB

Stainless steel valves

– Applicable occasions: corrosive media, food, medicine and other high cleanliness requirements

– Typical materials: 304, 304L,316, 316L,Duplex Stainless Steel 2205

Copper alloy valves

– Applicable occasions: seawater, drinking water, ships, water supply and drainage systems

– Typical materials: bronze, brass

Special alloy valves

– Applicable occasions: extreme corrosion, high temperature environment, such as chemical industry, nuclear power

– Typical materials: Monel, Hastelloy, titanium alloy

Types of Valves Selection Suggestions:

1. First consider the medium characteristics: such as corrosiveness, temperature, and pressure.

2. Secondly consider the working conditions: frequent operation, adjustment accuracy, etc.

3. Consider both economy and service life

4. For special working conditions, consult professional manufacturers such as JC Casting

Conclusion

The correct selection and rational use of types of valves are crucial to the safe and efficient operation of the system. JC Casting has its own independent factory and CNC machine tools. Years of casting experience enable it to provide customers with high-quality valve products and professional technical support. Whether it is conventional valves or special working condition solutions, JC Casting can provide you with satisfactory services.