What is the difference between SS 316 vs 17 4 PH?

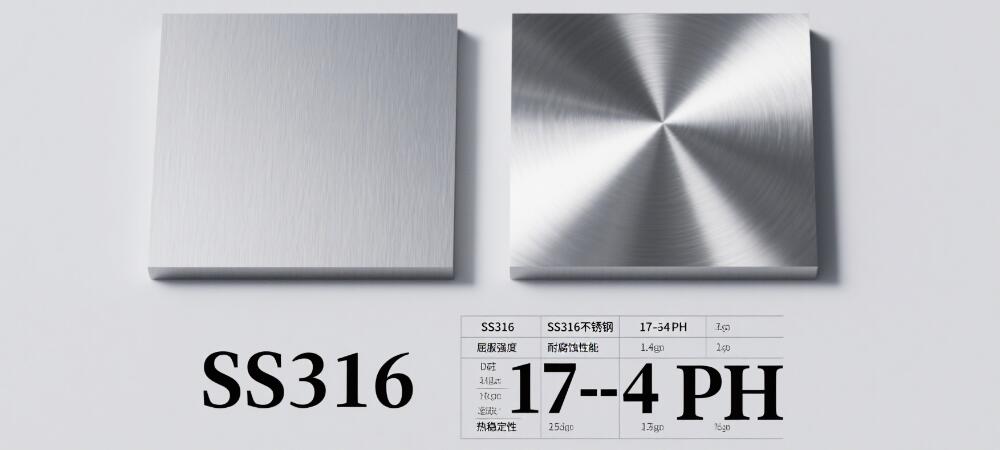

In stainless steel investment casting raw material choosing, SS316 and 17-4 PH are common used two types of stainless steel grades. SS316 is typical austenite stainless steel casting grade. 17-4 PH stainless steel is precipitation hardening material grade. Although both of them has high corrosion resistance. There are some differences in composition, properties, and applications between of them. Below are the SS 316 vs 17 4 PH compared points:

SS 316 vs 17 4 PH Chemical Content Difference

| Element Name | 316 Stainless Steel | 17 – 4 Stainless Steel |

|---|---|---|

| C | ≤0.08% | ≤0.07% |

| Si | ≤1.00% | ≤1.00% |

| Mn | ≤2.00% | ≤1.00% |

| P | ≤0.045% | ≤0.040% |

| S | ≤0.03% | ≤0.030% |

| Cr | 16.00 – 18.00% | 15.5 – 17.5% |

| Ni | 10.00 – 14.00% | 3.0 – 5.0% |

| Mo | 2.0 – 3.0% | 0 |

| Nb | 0 | 0.15 – 0.45% |

| Cu | 0 | 3.0 – 5.0% |

Performance Characteristics

Corrosion resistance

316 Stainless steel: Due to the addition of molybdenum, it excels in corrosion resistance. Especially it has strong resistance to chlorides and so on. Suitable for some harsh corrosive environments. Such as seawater environment, some corrosive media in the chemical industry.

17-4 Stainless steel: has good corrosion resistance. In the atmospheric environment,it can maintain good corrosion resistance. But, it is slightly inferior to 316 stainless steel chloride corrosion resistance.

Strength

316 Stainless Steel is an austenitic stainless steel. Strength is relatively low. But it has good toughness and ductility.

17 – 4 Stainless steel is a precipitation hardening stainless steel. Higher strength and hardness can be obtained through heat treatment. Its strength is significantly higher than 316 stainless steel. At the same time can still maintain a certain degree of toughness.

| MECHANICAL PROPERTIES & STRENGTH | ||

| GRADES >> | SS316 | 17-4PH |

| Tensile Strength Mpa | 545 | 1276 |

| Yield Strength Mpa | 275 | 1170 |

| Hardness (HB) | 220 | 350 |

| Elongation % | 50% | 8% |

Processing performance

316 stainless steel: good processing performance. Easy to cold work and welding. It is not easy to produce cracks and other defects during processing.

17-4 Stainless steel: Due to its high strength and hardness, it is relatively difficult to process. Higher requirements on processing technology and tools. But, it can be processed smoothly through appropriate process adjustment.

Application areas

316 Stainless steel: It is widely used in food processing equipment, medical equipment, chemical equipment, marine engineering, building decoration. For example, storage tanks and pipes in the food and beverage industry. Surgical instruments and medical equipment shells in the medical field. Marine parts and seawater desalination equipment in the marine environment.

17 4 Stainless steel: mainly used in occasions with high requirements for strength and corrosion resistance. Such as aerospace parts, nuclear industry equipment, valves in the petrochemical field, shaft parts. They have to be high strength and good corrosion resistance.

Typical Applications

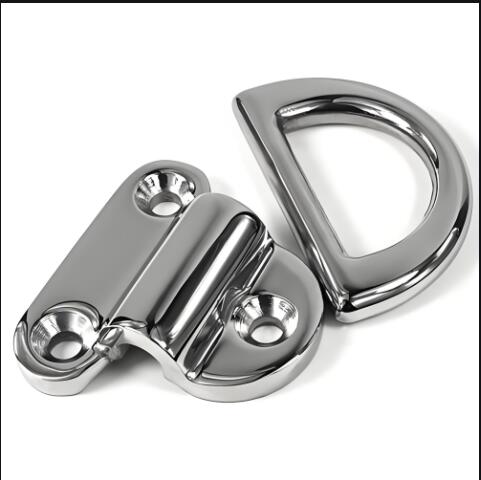

SS316 Marine Casting

17-4 PH Footpegs Sidestand Bracket

Price

316 Stainless steel: Because of high nickel content and added molybdenum element, its price is usually higher than ordinary stainless steel. And it belongs to medium-high price stainless steel material in the market.

17-4 Stainless steel: due to the relatively complex production process and the addition of a variety of alloying elements, its price is generally higher than 316 stainless steel. Belonging to the higher end of the stainless steel material.

How to choose SS316 or 17-4 PH Stainless Steel?

When choosing between SS316 or 17 – 4 PH stainless steel, we should consider the following factors.

Corrosion resistance:SS316 contains molybdenum element. It has excellent corrosion resistance. Especially in chloride-rich seawater environments. 17-4 PH’s Corrosion resistance is similar to 304 stainless steel.

If you are choosing a material with high corrosion resistance, SS316 is better!

Mechanical properties:SS316 has good ductility and toughness. It is easy to form and weld. Compared with 17-4 PH stainless steel, it has a relatively low yield strength. The typical yield strength is about 205 MPa. 17-4 PH is a precipitation hardening stainless steel. It can be heat treated to obtain high strength and hardness. After heat treatment, its yield strength can reach 758 MPa or higher.

If you are choosing a material with high hardness, 17-4 PH is better!

Heat resistance:SS316 can be used for high temperature applications up to about 870°C. Such as furnaces and heat exchangers. 17-4 PH May not perform as well as SS316 at very high temperatures. It is used in applications that need high strength and corrosion resistance at high temperatures. Such as aerospace and power generation.

If you are looking for a material with high heat resistance, SS316 is the better choice!

Cost:SS316 has a higher content of alloying elements (especially molybdenum). It is more expensive than 17-4 PH stainless steel.

If you are looking for a material with high corrosion resistance and low cost, 17-4 PH is the better choice!

In a word, if you need excellent corrosion resistance in harsh environments, good formability and weldability, SS316 is the first choice. If you need high strength, high hardness and moderate corrosion resistance, 17-4 PH stainless steel may be more suitable.